PERC Technology – Introduction

PERC (Passivated Emitter Rear Cell technology), or the production technology of P-Type photovoltaic cells and panels.

PERC technology is the most popular method of producing photovoltaic cells and solar panels. P-Type panels constitute approx. 70% of all produced photovoltaic modules in the world. Due to the fact that the technology has been leading in the last few years, the price and availability of these panels are at an optimal level. However, as with any technology, the peak of popularity often means the decline of dominance. In the case of PERC, there is also a slow technological regression and a shift from P-Type to N-Type and HJT.

How the PERC Cell Works?

Like all solar cells, P-TYPE converts sunlight into electricity.

A conventional photovoltaic cell works by converting sunlight directly into electricity.

Light is made of elementary particles called photons. Traveling at the speed of light, photons collide with the silicon in a solar cell. At this point, one of four things can happen to the photon:

The photon is reflected.

The photon passes directly through the solar cell.

The photon is absorbed by the cell and converted into heat.

The solar cell captures a photon and excites an electron to create electricity.

As you can see, not every photon produces electricity in a cell: in the case of PERC solar panels, the conversion efficiency hovers around 20%. The best series-produced P-Type photovoltaic panels reach 21%.

Solar cells are only capable of capturing photons within a certain energy range, therefore many photons simply pass or are absorbed by the silicon without exciting an electron and thus producing no electricity.

PERC is one of the technologies, next to HJT and sister N-TYpe, used to improve the capture rate.

How does PERC improve solar cell efficiency?

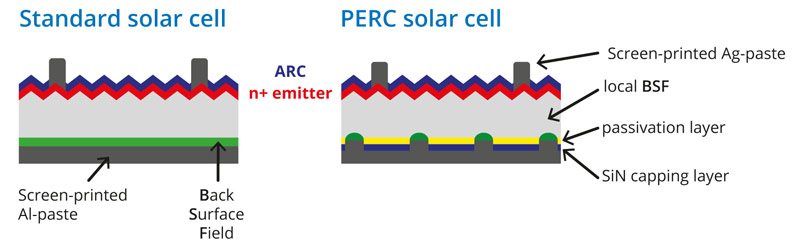

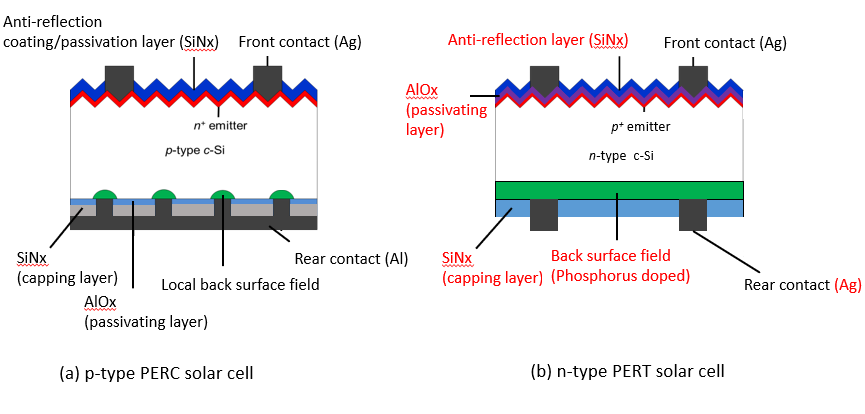

To increase the number of photons captured by the solar cell, PERC technology has two additional layers on the back of the cell. These layers improve the movement of electrons in the photovoltaic cell and also reflect light back into the solar cell, giving a second chance to capture electrons that would otherwise simply pass through the silicon.

P-TYPE vs N-TYPE

In some ways, solar cells are really simple. The light shines into them, precipitating electrons from silicon atoms. A cell is built in such a way that electrons are often blocked from returning to the atoms they came from. Instead, they travel through the fine mesh of wires at the top of the cell to the back of the cell and are transformed into electricity as they travel.

This is what happens in a P-type solar cell. Because P stands for positive and the photovoltaic cell has a positive base that attracts negatively charged electrons to it.

The exact opposite process takes place in N-type cells. Since the base is negative, the electrons travel from the negative bottom to the positive top.

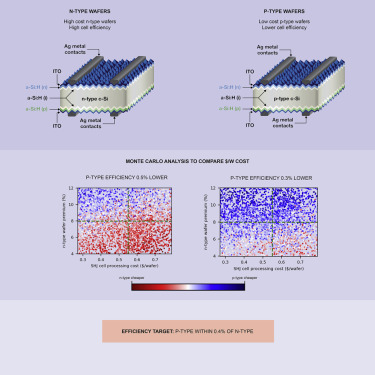

This is what N-cells do. Currently, they are only used by some manufacturers (Jolywood, AKCOME, Risen and Jinergy) of high-end panels. But because they provide an efficiency advantage and could eventually replace conventional P-type solar cells. This means that no electrons will be transported to the bottom of the solar cells anymore, which is good as this will improve the efficiency of the solar panels.

PERC worse than N-Type and HJT?

The biggest difference between N-type and P-Type is that ordinary P cells have the problematic element boron added to silicon, while N cells receive a much more optimal element – phosphorus.

Usually, the impurities in silicon are bad. But when it comes to getting solar cells to work, they must be “contaminated”.

This contamination is called enrichment and adding it is called enrichment. This causes a difference in electric charge between the top and bottom of the cell when light is shone on them.

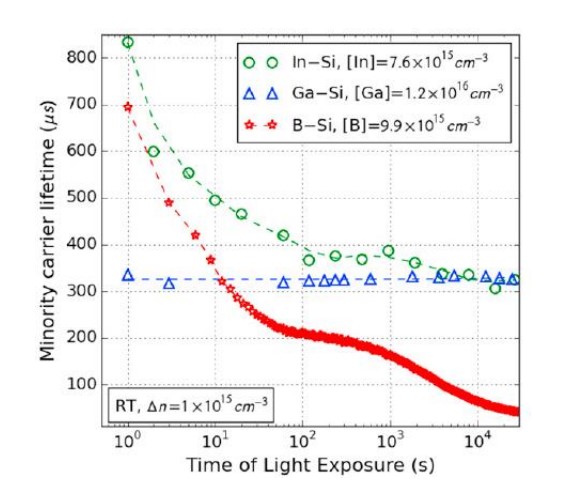

The boron used in P-cells works well but has some drawbacks. On the one hand, it causes light-induced degradation of the “LID”. It reduces solar panels’ efficiency by about 1.5% after their first few days in the sun. The LID effect is included in the power of the panels. This effect harms efficiency and is one of the reasons why even large investors are overly optimistic about how much electricity their PV systems and solar farms will generate.

Phosphorus does not have this effect, so N-type cells start with high efficiency, with no drop caused by the LID effect.

Another advantage is that certain types of contaminants in the production of photovoltaic cells apparently have less effect on N-type cells.

PERC panel – how does it work?

For the most commonly produced P-type silicon cells, the cell base is positive and the top portion is negative. The top layer of N-Type silicon, in which electrons accumulate, is called the emitter. Since the negative electrons at the top are blocked from following the shortest path to the positive atoms below, they pass through the fine mesh of wires on the cell’s surface and travel until they reach the bottom of the solar cell. Once they start their journey, it is possible to use them to generate electricity.

The electrons and atoms recombine under the metal contacts on the surface or back of the cell, reducing the voltage and limiting the output of the photovoltaic cell. This effect can be reduced by passivation, which means the first letter in PERC.

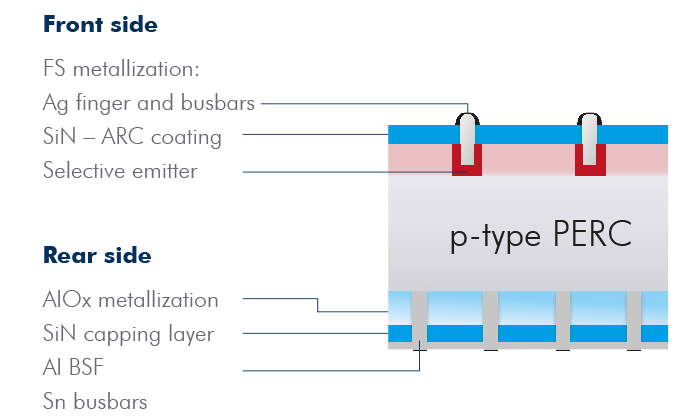

Passivation of a photovoltaic cell.

Passivation is the formation of a layer of oxidized material. The layer under the wire mesh on the surface of the PERC cell is usually aluminum oxide. On the back of the cell is aluminum oxide or silicon oxide, followed by a layer of silicon nitride. All of this folds into four letters in PERC – Passivated Emitter and Rear CELL, i.e. the rear cell.

On the back of the cell, the metal contacts still need to touch the silicon cell. Therefore, when using a laser to cut holes in the back passivation layer, holes are created for the metal contacts to enter.

PERC Cell Efficiency

AKCOME declares for its latest series PERC GA bifacial, double glass (with gallium) from 22% to 22.5% of the efficiency of the silicon used in the P-Type technology.

Jinergy, on the other hand, in the case of its photovoltaic cells PERC GA declares at the level of 22.8%

Effectiveness of PERC Panels

AKCOME for Half-CUT P-Type modules achieves an efficiency of between 19.5% and 20.5%. Please note that these are Double Glass modules.

Jinergy in the PERC solar panel also achieves efficiency levels of 19.5-20.5 %%, which is also a solid result.

PERC POWER

AKCOME nominally offers, depending on the size of the cells:

355W-375W in the HalfCUT series

430W-450W in a series of 144 cells

Jinergy offers in the Half-Cut glass-glass series the appropriate:

120 cells 370W-390W

144 cells 430W-450W

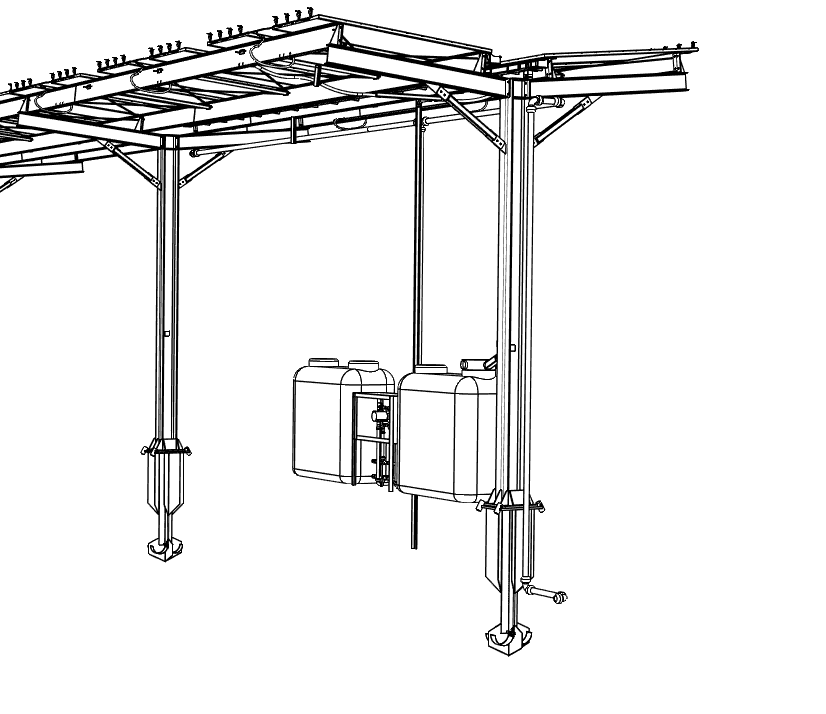

Solar farm – PERC panels

In terms of price, PERC panels are certainly dedicated to large investments. Most of the photovoltaic farms and solar power plants work on P-cells. To maximize the potential of this technology, you should choose bifacial panels with a double glass structure (GLASS-GLASS). Combined with the lower degradation of the Gallium enriched silicon, it generates significant savings over 30 years of use over conventional PERC panels.

- Up to 15% more production in 30 years

- Up to 9.3% Construction cost decreased

- 6.4% lower cost of connectors and cables

- Up to 10.4% lower labor costs

- LCOE reduction by 4.4%

- Up to 20% lower BOS costs

ADVANTAGES AND DISADVANTAGES PERC TECHNOLOGY

The Best Solar Panels – Type P?

Gallium-Dopped Silicon (GA) solar cells showed an efficiency improvement of 0.06-0.12% by optimizing the cell manufacturing process. Compared to Boron-doped tiles.

In the last few years, the phenomenon of degradation of solar cell/module performance caused by light and elevated temperature “LeTID” has attracted attention. LeTID is believed to be caused by the interaction between metal contamination and hydrogen in the production of silicon wafers. In the case of Gallium doped solar cells, it is easier to control LeTID as there is no need to introduce excessive amounts of hydrogen into the cell processing to attenuate the LID, which is required with Boron doped wafers.

PERC GA dopped with Gallium.

LID and LeTID problems can be effectively solved by using monocrystalline gallium silicon wafers. Compared to the boron enriched silicon wafer, the gallium silicon wafer can improve the performance of PERC cells to some extent.

PERC cells with gallium do not have a boron-oxygen defect, so the typical boron-oxygen LID phenomenon does not occur.

Research strongly suggests that the use of gallium-enriched silicon wafers can effectively mitigate the initial LID that degrades the performance of Type P boron silicon wafers.

PERC Panels price

Due to the popularity of the technology and the multitude of producers, the price of P-Type photovoltaic cells and panels is their greatest advantage. In the direct purchase of TIER-II producers or not qualified in Bloomberg, the price can be as high as EUR 0.180 per W / p. However, to have a guarantee of 30-year reliability and the highest efficiency, the price for the PERC bifacial module is in the range of EUR 0.200-0.215 per W/p.

PERC panel and Bifaciality

The bilateral or bifacial PERC is around 70%. It is noticeably less than with the N-Type panels, especially the HJT. Nevertheless, the glass-glass configuration with bifacial energy production is the best choice for large projects such as business installations and solar farms.

Most Popular

Kapaciteti Srbije za Fotonaponsku (PV) Energiju

Serbia Capabilities for Photovoltaic (PV) Energy

Subscribe To Our Weekly Newsletter

Categories

- HJTPV.com

- HJT Technology

- HJT Producers

- HJT Solar Panels

- HJT Solar Panel Mysolar Gold 740W

- HJT Solar Panel Mysolar Gold 640W

- HJT Solar Panel AEsolar COMET 720W

- HJT Solar Panel AESOLAR COMET 650W

- HJT Solar Panel Bi Chaser Akcome 120 Cells

- HJT Solar Panel HuaSun HS-B120DS

- HJT Solar Panel Jinergy JNHM120 Cells

- HJT Solar Panel Risen Hyper-ion

- HJT Solar Panel QW Solar Giwa5 730W

- HJT Solar Panel QW Solar Giwa5 640W

- HJT Solar Panel Risen RSM120

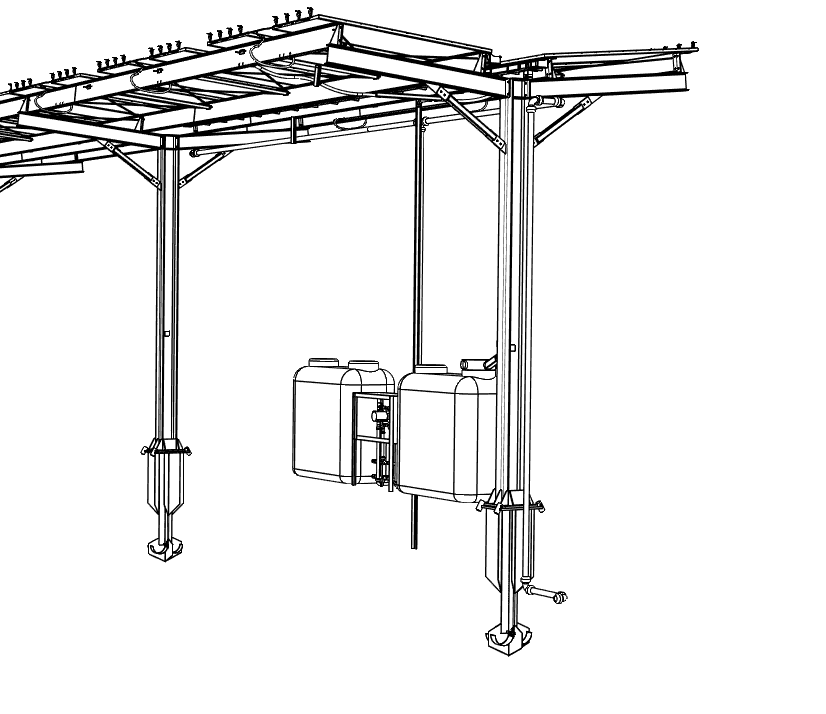

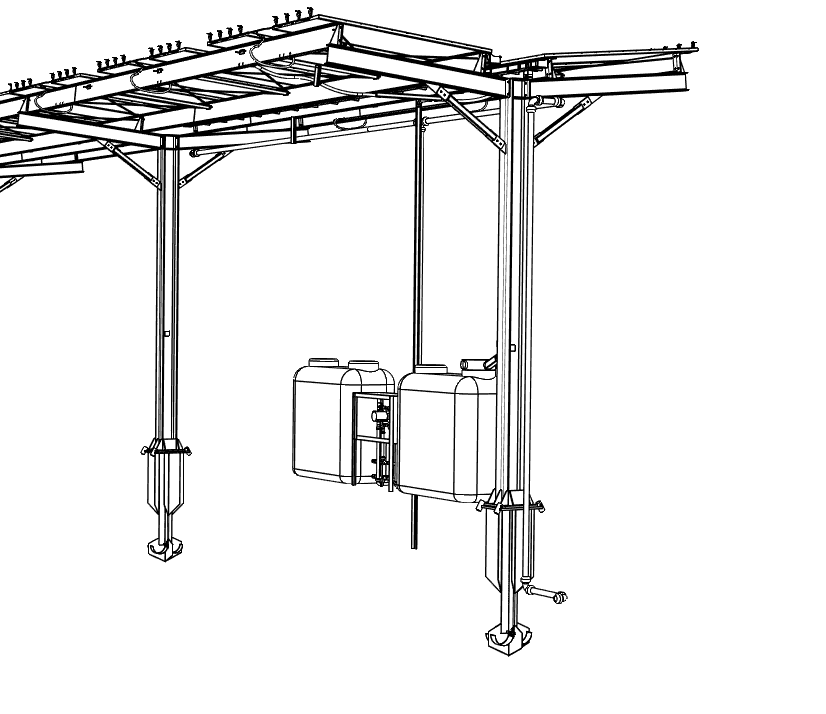

- Cleaning Robot

- HJT Solar CELLS

- News&Knowledge

- Contact

- HJTPV.com

- HJT Technology

- HJT Producers

- HJT Solar Panels

- HJT Solar Panel Mysolar Gold 740W

- HJT Solar Panel Mysolar Gold 640W

- HJT Solar Panel AEsolar COMET 720W

- HJT Solar Panel AESOLAR COMET 650W

- HJT Solar Panel Bi Chaser Akcome 120 Cells

- HJT Solar Panel HuaSun HS-B120DS

- HJT Solar Panel Jinergy JNHM120 Cells

- HJT Solar Panel Risen Hyper-ion

- HJT Solar Panel QW Solar Giwa5 730W

- HJT Solar Panel QW Solar Giwa5 640W

- HJT Solar Panel Risen RSM120

- Cleaning Robot

- HJT Solar CELLS

- News&Knowledge

- Contact

Related Posts

Maximizing Agrivoltaic Performance with HJT/TOPCon Modules

MySolar a solar panel manufacturer, announced in 2023 that it has launched commercially available HJT + perovskite solar cells with a power output of 250 W. The company was founded in 2013 and has since become one of the leading solar panel manufacturers in Poland. HJT + perovskite cells are a new technology with the potential to revolutionize the solar industry.

Innovative 5MW Solar Farm in Northern Italy: Energy Excellence Meets Sustainable Agriculture

MySolar a solar panel manufacturer, announced in 2023 that it has launched commercially available HJT + perovskite solar cells with a power output of 250 W. The company was founded in 2013 and has since become one of the leading solar panel manufacturers in Poland. HJT + perovskite cells are a new technology with the potential to revolutionize the solar industry.

Kapaciteti Srbije za Fotonaponsku (PV) Energiju

Kapaciteti Srbije za PV Instalacije 1. Obilje pogodnog zemljišta: Srbija ima velike površine zemljišta pogodnog za fotonaponske (PV) instalacije. Topografija zemlje uključuje ravne ravnice, posebno

Serbia Capabilities for Photovoltaic (PV) Energy

Serbian Land Capabilities for PV Installations 1. Abundance of Suitable Land:Serbia has vast expanses of land suitable for photovoltaic (PV) installations. The country’s topography includes