- HJTPV.com

- HJT Technology

- HJT Producers

- HJT Solar Panels

- HJT Solar Panel Mysolar Gold 740W

- HJT Solar Panel Mysolar Gold 640W

- HJT Solar Panel AEsolar COMET 720W

- HJT Solar Panel AESOLAR COMET 650W

- HJT Solar Panel Bi Chaser Akcome 120 Cells

- HJT Solar Panel HuaSun HS-B120DS

- HJT Solar Panel Jinergy JNHM120 Cells

- HJT Solar Panel Risen Hyper-ion

- HJT Solar Panel QW Solar Giwa5 730W

- HJT Solar Panel QW Solar Giwa5 640W

- HJT Solar Panel Risen RSM120

- Cleaning Robot

- HJT Solar CELLS

- News&Knowledge

- Contact

- HJTPV.com

- HJT Technology

- HJT Producers

- HJT Solar Panels

- HJT Solar Panel Mysolar Gold 740W

- HJT Solar Panel Mysolar Gold 640W

- HJT Solar Panel AEsolar COMET 720W

- HJT Solar Panel AESOLAR COMET 650W

- HJT Solar Panel Bi Chaser Akcome 120 Cells

- HJT Solar Panel HuaSun HS-B120DS

- HJT Solar Panel Jinergy JNHM120 Cells

- HJT Solar Panel Risen Hyper-ion

- HJT Solar Panel QW Solar Giwa5 730W

- HJT Solar Panel QW Solar Giwa5 640W

- HJT Solar Panel Risen RSM120

- Cleaning Robot

- HJT Solar CELLS

- News&Knowledge

- Contact

Full-Automatic & Professional Robotic Solar Panel Cleaner

Solarwalker s1

On this Site You Will Read About

How to Clean Solar Panel?

SolarWalker s1 PV Cleaner Robot

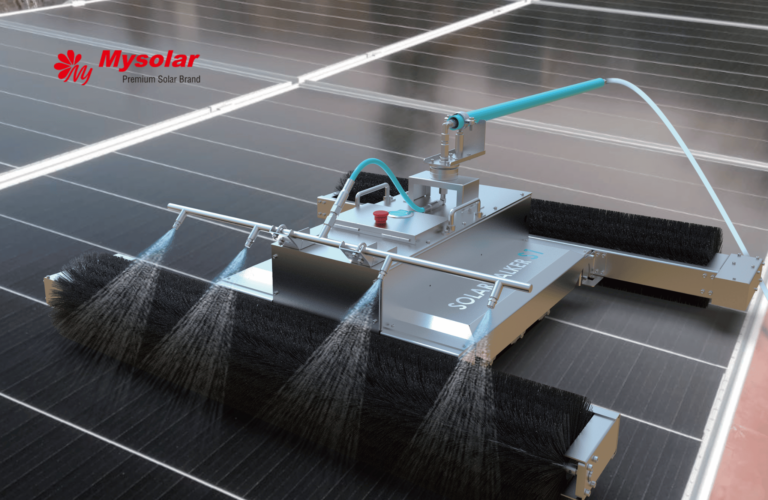

A solar panel cleaning robot “SolarWalker” is an autonomous machine designed to clean solar panels efficiently and effectively. The purpose of such a robot is to remove dust, dirt, debris, and other contaminants from the surface of solar panels, thereby optimizing their performance and energy output.

The combination of a solar cleaning robot with HJT (Heterojunction) solar panels can be advantageous for power output. It’s important to note that regular cleaning is beneficial for any type of solar panel, regardless of the technology used. However, the synergy between HJT panels and a solar cleaning robot is help harness the full potential of HJT technology by ensuring optimal cleanliness, performance, and power output, especially in solar farms and utility-scale PV businesses.

5% to 30% more Power

Dust, dirt, and debris accumulation on solar panels can reduce their efficiency and hinder sunlight absorption. Cleaning the panels removes these obstructions, allowing them to capture more sunlight and generate more electricity.

Improved return on investment (ROI)

By maximizing energy production, cleaning solar panels helps ensure a higher return on investment. The additional electricity generated from clean panels can result in more savings on electricity bills or increased revenue from selling excess power back to the grid.

PV Robot Cleaner Advantages

Long-term system performance

Over time, dirt and debris build-up on solar panels can lead to permanent damage if left unattended. Cleaning them regularly helps maintain the panels' performance and extends their lifespan. By protecting the panels from potential damage, cleaning contributes to the long-term reliability of the solar energy system.

Maintenance detection

Cleaning solar panels allows for close inspection of the panels' condition. It helps identify any potential maintenance issues, such as loose connections, cracked panels, or faulty wiring. Early detection enables timely repairs, preventing further damage and minimizing downtime.

Efficient and Portable

- Slim & Portable Design

- Dry Sweeping & Wet Washing

- 0-20° Sweeping Angle

- 0-15° Washing Angle

- Dual Beater Brushes

- Detachable Battery Pack

- Anti-explosion Battery

- App and Remote Controlable

- 3600hrs Warranty

- OTA Upgrading and Remote Monitoring

- Compatible to M2/M4/M6/M10/G1/G12 cells

Specifications

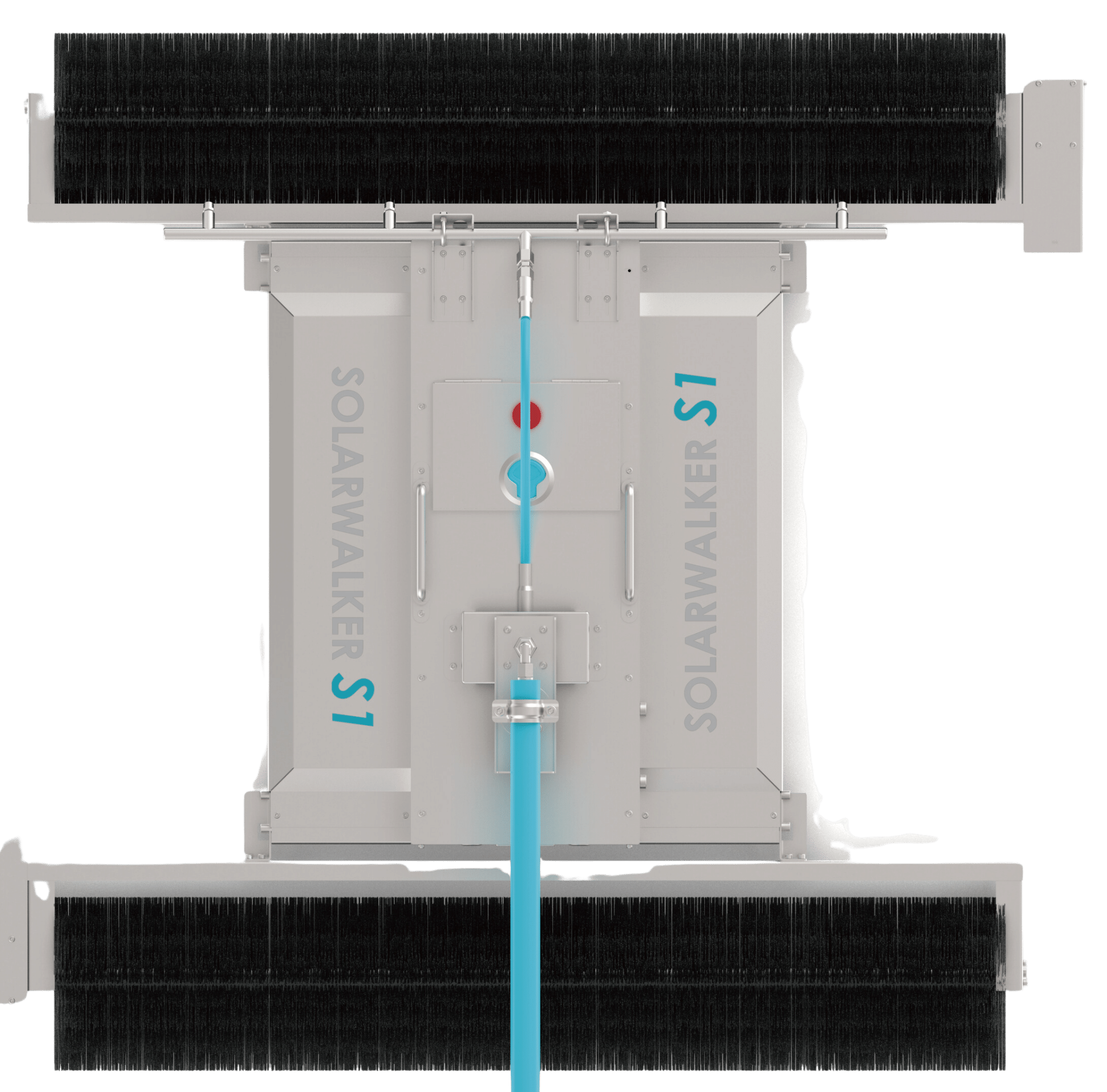

- Model No.:SOLARWALKER S1

- Working Time: Abt 4-5 hours

- Dimension: 676*585*275mm

- Input Voltage: 110-240V AC

- Battery: 16.8 Ah

- Panel Installation Angle :15-20°

- IP Grade: IP65

- Control Mode: APP/Remote

- Gross Weight:28.0±2%

- Combined Dry Sweeping & Washing

- Cleaning Efficiency: >=680sqm/hour

- Maximum Cleaning Area/Hour: 120kw

Solar Panel Cleaning Robot Overall informations

Solar Walker S1

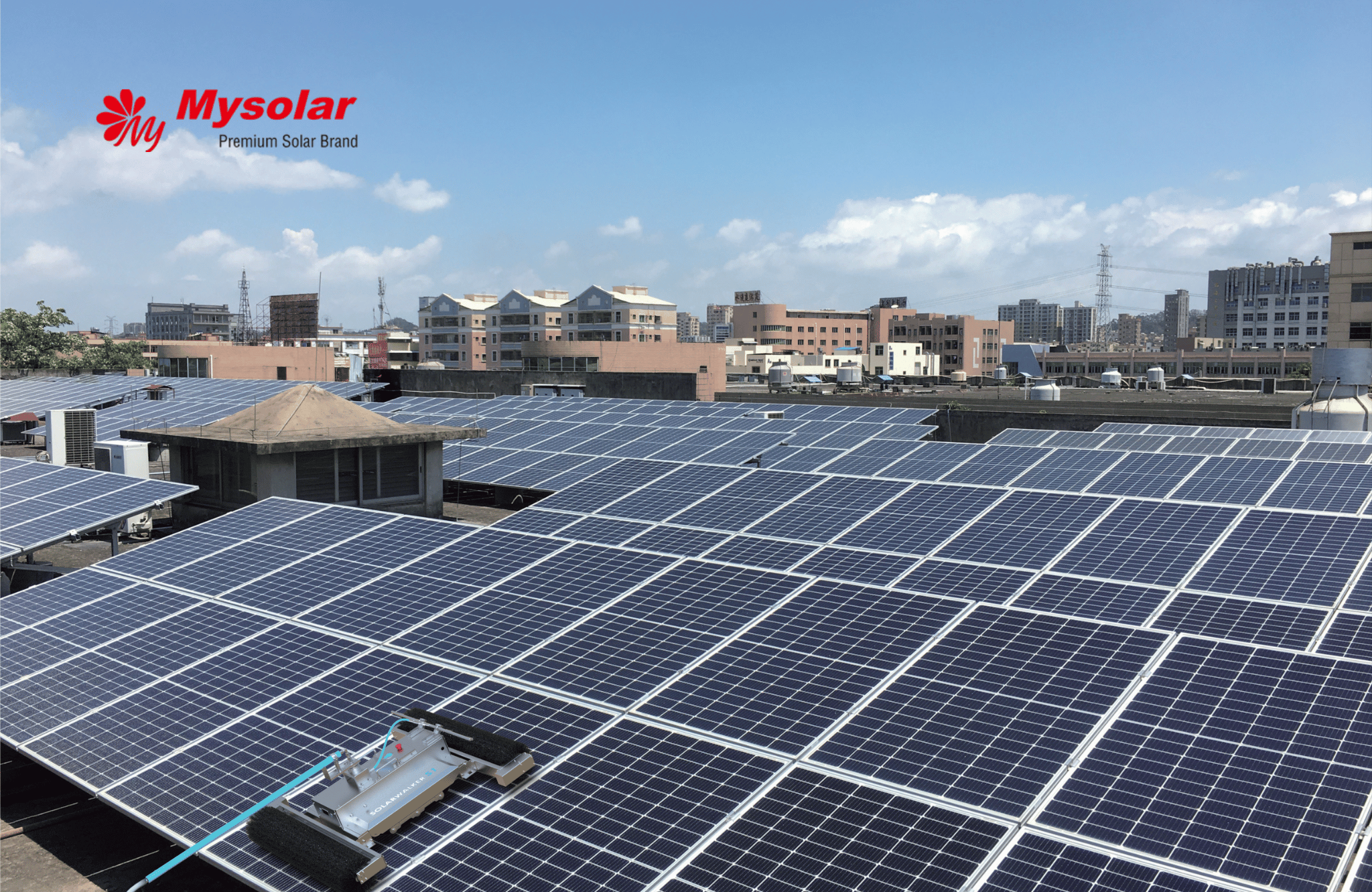

Cleaning system for solar farm

A solar cleaning robot designed for solar farms can provide several benefits in terms of efficiency and cost-effectiveness. Here are some advantages of using a solar cleaning robot for large-scale solar farms:

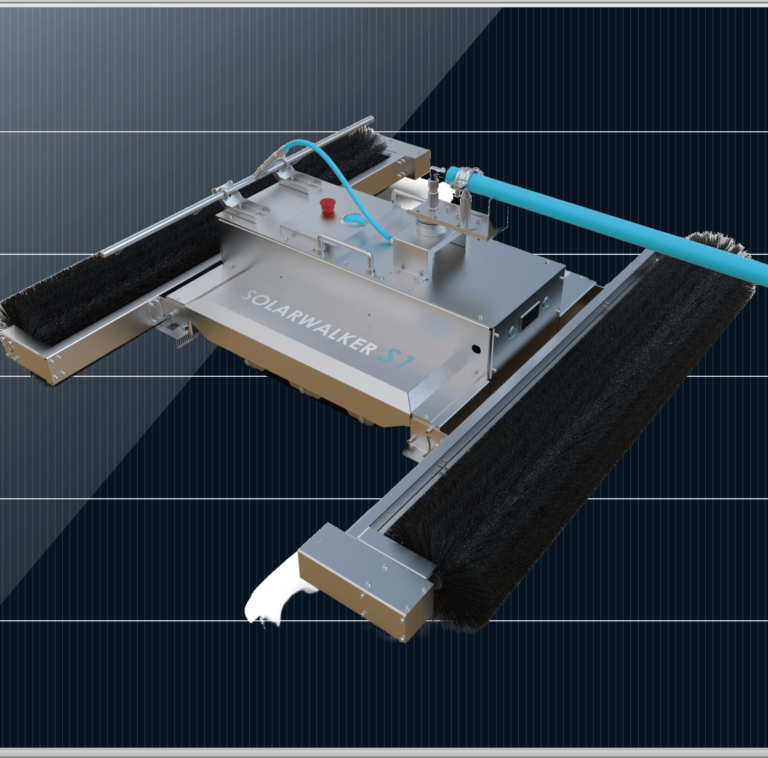

Time and labor savings: Solar farms typically consist of a vast number of solar panels, making manual cleaning a time-consuming and labor-intensive task. A solar cleaning robot can automate the cleaning process, significantly reducing the time and effort required by human workers. It can clean multiple panels simultaneously and operate autonomously, allowing workers to focus on other important tasks.

Increased cleaning accuracy and consistency: The precise movements and cleaning patterns of a robot ensure consistent and thorough cleaning of each solar panel. Unlike manual cleaning, which can vary in quality depending on the worker’s technique, a robot follows programmed paths to ensure uniform cleaning across the entire solar farm. This results in optimized energy production and improved overall system performance.

Enhanced safety: Cleaning solar panels on large-scale solar farms can involve working at heights or in challenging terrain. By utilizing a solar cleaning robot, the need for workers to physically access the panels is reduced, minimizing the risk of accidents or injuries. The robot can navigate difficult terrain and handle cleaning tasks with built-in safety features.

Cost-effective maintenance: A solar cleaning robot can help reduce maintenance costs associated with manual cleaning methods. By automating the cleaning process, it eliminates the need for hiring additional cleaning crews or outsourcing the task to third-party cleaning services. The upfront investment in a solar cleaning robot can be offset by long-term savings in labor and maintenance expenses.

Improved energy production: Solar panels that are regularly cleaned by a robot maintain optimal efficiency and generate more electricity. The removal of dust, dirt, and debris ensures maximum sunlight absorption and prevents shading or hotspots on the panels. This leads to increased energy production, higher energy yields, and improved financial returns for the solar farm.

Remote monitoring and control: Many solar cleaning robots come equipped with remote monitoring and control capabilities. This allows operators or maintenance personnel to remotely monitor the robot’s performance, schedule cleaning cycles, and receive real-time data on the cleanliness and condition of the solar panels. Remote control features enable efficient management and troubleshooting, reducing downtime and maximizing the robot’s productivity.

Adaptability to various terrains and weather conditions: Solar cleaning robots are designed to operate in different types of terrains found in solar farms, including uneven surfaces or slopes. They are also built to withstand various weather conditions, such as rain, heat, and cold temperatures. This adaptability ensures consistent cleaning performance regardless of the environmental challenges.

Overall, utilizing a solar cleaning robot for solar farms streamlines the cleaning process, improves energy production, and reduces operational costs. By automating the cleaning tasks, solar farm operators can maximize the performance and longevity of their solar panels while optimizing the return on investment.

Here are some key features and considerations for a solar panel cleaning robot:

Feature of a good PV Modules&Cell?

HJT efficiency can achieve even 27%. But usually producers like HuaSun or Jinergy use Heterojunction solar cells with 24%-24,5% efficiency. Compare to PERC Cell, HJT can achieve even 20% more power.

HJT solar panels have the best efficiency in serial production. Scope of it is between 21%-22,5% with R&D plan even to 26%. HJT module has the best performance and most reliable characteristic resistance for most common fail from all over solar technology.

HJT solar Panels with 120 cells have a scope of power between 370W-390W and for 144 cells 425W – 470W. At the end of 2021 Power of HJT modules will achieve >500W and in soon future will be >600W.

HJT technology ensures a long safe warranty for 30 years of production and 12 -25 years for a panel, depends on the producers. It’s more approx. 5 years than common PERC panels.

The combination of a solar cleaning robot with HJT (Heterojunction) solar panels can indeed be advantageous for power output?

Here’s why:

Enhanced efficiency: HJT solar panels are known for their high efficiency, as they combine the advantages of traditional crystalline silicon solar cells with thin-film technology. By incorporating layers of amorphous silicon on top of the crystalline silicon cells, HJT panels can achieve higher conversion efficiencies. When combined with regular cleaning by a solar cleaning robot, the panels can maintain optimal efficiency levels by removing any dust, dirt, or debris that may hinder sunlight absorption. This synergy between HJT panels and a cleaning robot ensures maximum power output.

Improved performance in low light conditions: HJT solar panels are also known for their excellent performance in low light conditions, such as cloudy or overcast weather. They have a lower temperature coefficient and can generate electricity even when sunlight intensity is relatively low. Regular cleaning of HJT panels ensures that they can capture as much available light as possible, maximizing their performance in all lighting conditions.

Reduction of hotspots: HJT solar panels are less susceptible to hotspots compared to traditional crystalline silicon panels. Hotspots occur when certain areas of a solar panel are shaded or damaged, leading to localized heating and reduced efficiency. By keeping HJT panels clean, the solar cleaning robot helps prevent shading and ensures uniform sunlight distribution across the panel surface, minimizing the risk of hotspots and optimizing power output.

Long-term reliability: Both HJT solar panels and a solar cleaning robot contribute to the long-term reliability of a solar energy system. HJT panels are known for their durability and long lifespan. Regular cleaning removes contaminants that could potentially cause damage or degrade the panel’s performance over time. By maintaining the cleanliness of HJT panels, the solar cleaning robot helps prolong their lifespan and ensures consistent power output throughout the system’s operational life.

Cost-effectiveness: HJT solar panels are a higher-end technology with higher upfront costs compared to conventional panels. Maximizing their power output through regular cleaning can help maximize the return on investment. By preventing performance degradation and maintaining optimal efficiency, the combination of a solar cleaning robot and HJT panels can contribute to long-term cost savings and increased financial returns.

It’s important to note that regular cleaning is beneficial for any type of solar panel, regardless of the technology used. However, the synergy between HJT panels and a solar cleaning robot can help harness the full potential of HJT technology by ensuring optimal cleanliness, performance, and power output.

Best in Class Solar Panels

BEST HJT Solar Panels

Discover Best Review

HJT Producers Review

Best solar cells and solar modules producers. Heterojunction globally leaders with a wide spectrum of power and dimension for utility-scale projects, solar farms, commercial and residential.

MeyerBurger

Hevel

Enjoy The Solar Future

Purchase HJT CELLS

Best prices for HJT solar CELLS direct from producers with no hide margin. How we manage deals for our Customers:

First of all analyze needs

Preparing few options

Negotiating best prices

Agreeing of payment policy

Managing delivery and shipment

Helping with a service issue

Best Solar Panels for Utility

Our dedicated offer for a solar projects like:

- solar farms

- solar plants

- utility-scale solar roof installation

- solar cities

- hydrogen electrolyzer installations

MYSOLAR Solar Panel

-

Bifacial

-

Glass-Glass

-

Half-cut

-

>91,75% Power After 30 Years

-

Additional Insurance Dedicated For EPC & Investors

-

30/30 years warranty

MYSOALAR HJT Solar Cells Purchasing

Long Term Cooperation

MYSOLAR production abilities count in GW helps ensure long-term cooperation with any Client who needs the best HJT solar cell.

WIN&WIN Solutions

Technical Background about HJT Cell manufacturing and Client Final Product with best HJT Modules abilities.

Experience in ODM Model

TIER I Partner on solar cell Clients list gives necessary experience to build dedicated cooperation model for Europe Solar Producers.