The story of Heterojunction (HJT) technology in solar photovoltaics is one of innovation and evolution, focusing on enhancing efficiency, performance, and durability. Below is a brief history of its development:

Early Development in the 1980s

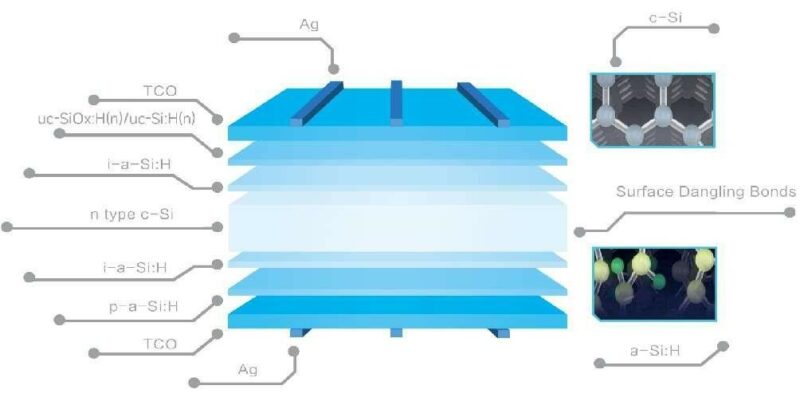

- Origin at Sanyo: The roots of HJT technology can be traced back to the 1980s when Sanyo, a Japanese electronics manufacturer (later acquired by Panasonic), developed the “Heterojunction with Intrinsic Thin Layer” (HIT) cell. The idea was to combine the benefits of both crystalline and amorphous silicon to create a solar cell with high efficiency and excellent surface passivation.

Commercialization and Growth in the 1990s-2000s

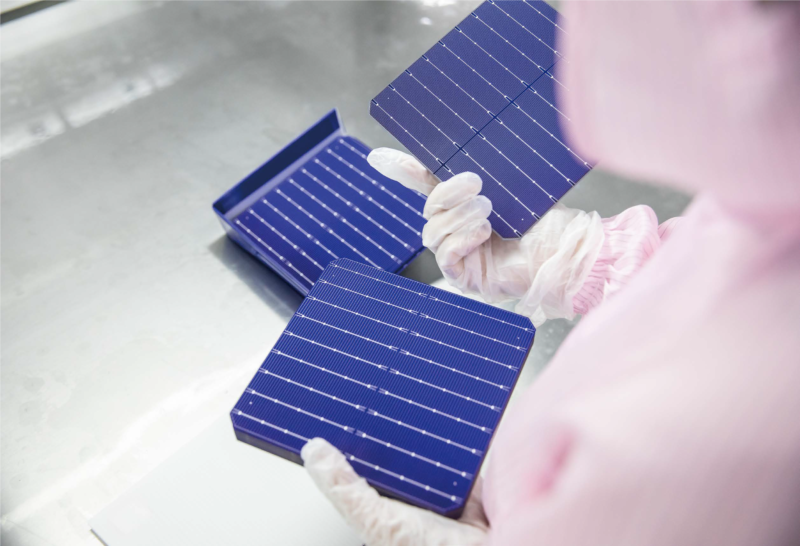

- First Commercial HIT Cells: By the 1990s, Sanyo had commercialized the HIT technology. The key innovation was to use a crystalline silicon (c-Si) wafer as the core for high conductivity and two thin layers of amorphous silicon (a-Si) on either side for better surface passivation, reducing electron recombination and enhancing efficiency.

- Higher Efficiency and Temperature Performance: Throughout the 2000s, HIT cells became known for their high conversion efficiencies, low temperature coefficient (superior performance in heat), and low degradation rates compared to conventional cells.

Acquisition by Panasonic and Further Innovations (2010s)

- Panasonic’s Improvements: When Panasonic acquired Sanyo in 2010, it further refined the HJT process. By focusing on manufacturing efficiency and cell design, Panasonic was able to produce cells that reached world-record efficiencies (up to 24% in the lab and around 22-23% in commercial production).

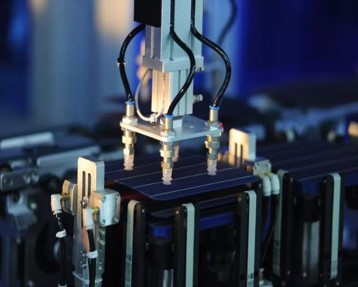

- Improvement in Manufacturing Process: During this period, developments in transparent conductive oxides (TCOs) and improvements in laser and deposition techniques contributed to more efficient HJT production and a reduction in costs.

Industry-Wide Adoption and Technological Advances (2015-present)

- Broader Market Adoption: By the mid-2010s, other companies began investing in HJT technology, recognizing its potential for high efficiency and long-term stability. Manufacturers in China, Europe, and the U.S. started incorporating HJT technology into their product lines, seeing it as a natural successor to PERC (Passivated Emitter Rear Cell) and other existing technologies.

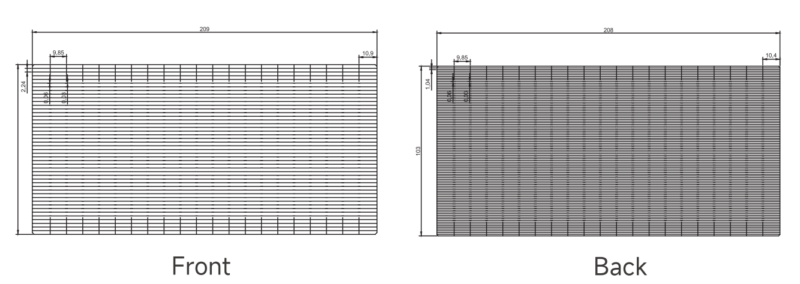

- Zero Busbar (0BB) Integration and Bifacial Modules: Innovations like Zero Busbar (0BB) technology (where busbars are eliminated to improve light absorption and efficiency) and bifacial modules (which can capture light from both the front and back) were adopted to maximize the energy yield of HJT cells.

Current Status and Future Outlook

- Increasing Efficiency and Reducing Costs: Today, HJT modules are among the highest efficiency commercial PV products, with typical efficiencies of 22-24%. The cost of manufacturing has continued to decrease due to advances in materials and production techniques, such as Smart Wire Technology (SWCT), which replaces traditional busbars with fine wires to enhance current collection and performance.

- Competition with Other High-Efficiency Technologies: HJT competes with other high-efficiency technologies like TopCon (Tunnel Oxide Passivated Contact) and perovskite-based tandem cells. However, HJT remains a favorite for its high performance, particularly in bifacial designs and its lower degradation rates over time.

In summary, the story of HJT technology is marked by its origins in Japan, its growth through technological improvements and efficiency breakthroughs, and its current status as a leading technology in the PV industry due to its superior performance, longevity, and potential for further optimization. With ongoing research and market interest, HJT continues to be a prominent player in the future of solar energy.

HJT technology, with its variations in 0BB, HBC, and tandem perovskite cells

Introduction

HJT (Heterojunction Technology) is gaining popularity in the photovoltaic industry due to its numerous advantages, including high efficiency, low degradation rates, resistance to LID (Light-Induced Degradation) and PID (Potential-Induced Degradation), and superior performance under low-light conditions. The three main directions shaping HJT’s development – 0BB (Zero Busbar), HBC (Heterojunction with Back Contact), and the integration of perovskites – are driving innovation in the sector. Below is a detailed breakdown of the technical parameters of each technology, focusing on efficiency, temperature coefficients, bifaciality, resistance to LID and PID, and overall performance.

HJT 0BB Technology (Zero Busbar)

Zero Busbar (0BB) technology is an advanced design in solar photovoltaic (PV) cells where the traditional metal busbars are completely removed from the surface of the cell. In standard solar cells, busbars are metal strips printed on the cell surface to collect and transfer electrical current. However, in 0BB technology, alternative methods like conductive adhesives, smart wire technology (SWCT), or ultra-thin wires are used to replace the busbars.

- Cell and Module Efficiency:

- HJT modules using 0BB technology can achieve power outputs ranging from 700 W to 730 W, with module efficiency reaching around 22.5-23%.

- The efficiency of HJT 0BB cells can exceed 25%, making them some of the most efficient cells available.

- Temperature Coefficient:

- 0BB HJT modules have an exceptionally low temperature coefficient, which can reach -0.24%/°C. This low coefficient means reduced performance loss in high temperatures, which is crucial for installations in warm climates.

- Bifaciality:

- HJT cells exhibit a high bifaciality coefficient, which refers to their ability to capture light from both the front and back sides of the cell. For 0BB modules, bifaciality can range from 85-90%, significantly enhancing energy production.

- Resistance to PID, LID, and Hot Spot:

- PID (Potential-Induced Degradation): HJT 0BB modules are nearly immune to degradation caused by voltage stress, which enhances their long-term durability.

- LID (Light-Induced Degradation): Due to the use of n-type materials, HJT cells experience minimal LID, generally below 0.5% in the first year.

- Hot Spot Resistance: The thin conductive mesh of the 0BB design greatly reduces the risk of hot spot formation, improving the efficiency and durability of the modules.

- Better Performance in Low Light Conditions:

- 0BB HJT modules perform exceptionally well under low light conditions, thanks to their low conductive losses and optimized light absorption.

HBC Technology (Heterojunction with Back Contact)

HBC technology (Heterojunction with Back Contact) is an advanced solar cell design that combines two cutting-edge technologies: heterojunction (HJT) and interdigitated back contact (IBC). This hybrid approach merges the high efficiency and low degradation advantages of HJT with the performance benefits of a back-contact design, further enhancing the overall power output and efficiency of the solar cell.

- Cell and Module Efficiency:

- HBC cells achieve some of the highest efficiency levels in HJT technology, exceeding 26% for the cells themselves.

- HBC module efficiency surpasses 23%, leveraging the full light absorption on the front surface and optimized current flow.

- Temperature Coefficient:

- HBC technology also boasts a low temperature coefficient, typically around -0.25%/°C, or even lower in some cases, making it well-suited for high-temperature environments.

- Bifaciality:

- HBC modules, like their 0BB counterparts, maintain high bifaciality levels of around 85-90%, contributing to enhanced energy generation from reflected light.

- Resistance to PID, LID, and Hot Spot:

- PID: As part of the HJT family, HBC cells are highly resistant to PID, ensuring stable long-term performance.

- LID: The back contact structure minimizes LID effects, ensuring prolonged module efficiency.

- Hot Spot Resistance: The absence of busbars on the front surface and the effective conductive network reduce the occurrence of hot spots.

- Better Performance in Low Light Conditions:

- HBC modules excel under low-light conditions due to their enhanced light absorption capabilities and minimized conductive losses.

Integration of Perovskite with HJT

Combining perovskite with Heterojunction (HJT) technology is an exciting and innovative approach aimed at further boosting the efficiency of solar cells by leveraging the strengths of both technologies. This hybrid structure is often referred to as a tandem solar cell because it stacks two different types of photovoltaic materials—perovskite on top of HJT—in a way that allows each material to absorb different parts of the solar spectrum.

- Cell and Module Efficiency:

- Tandem cells combining perovskite and HJT can achieve impressive efficiencies, surpassing 30% in lab conditions. Commercially available modules reach efficiencies in the range of 25-27%.

- Temperature Coefficient:

- The temperature coefficient of tandem HJT + perovskite cells is around -0.26%/°C or lower, ensuring high efficiency even under elevated temperatures.

- Bifaciality:

- While tandem modules with perovskites can be bifacial, their bifaciality coefficient might be slightly lower than traditional HJT cells, depending on the module design.

- Resistance to PID, LID, and Hot Spot:

- Although the integration of perovskites can increase the risk of degradation, advanced protective technologies are employed to minimize PID and LID effects.

- Optimized module structure reduces the occurrence of hot spots.

- Better Performance in Low Light Conditions:

- Tandem HJT + perovskite cells can effectively utilize a broader spectrum of sunlight, enhancing performance even in low irradiance conditions.

Comparison HJT with TOPCon Technology

- Efficiency: HJT technology (including 0BB, HBC, and tandem cells with perovskites) exceeds 25-26% cell efficiency, whereas TOPCon technology typically reaches 22-23% for modules and 24-25% for cells.

- Temperature Coefficient: HJT boasts a lower temperature coefficient of around -0.24 to -0.25%/°C, while TOPCon usually has a coefficient of about -0.29%/°C, indicating greater efficiency loss under high temperatures.

- Annual Degradation: HJT modules have a lower annual degradation rate of 0.25-0.3% after the first year, while TOPCon modules generally show a higher degradation rate of around 0.4% annually.

- Bifaciality: Both 0BB and HBC HJT modules offer bifaciality coefficients of 85-90%, which is generally higher than TOPCon modules.

- Resistance to PID, LID, and Hot Spot: Unlike TOPCon, which can be more susceptible to PID and LID, HJT cells (especially in 0BB and HBC forms) exhibit strong resistance to these effects, ensuring better long-term performance.

- Low-Light Performance: HJT cells outperform TOPCon in low-light conditions, maintaining high energy generation even under suboptimal lighting, such as cloudy days or lower angles of sunlight incidence.

Heterojunction Solar Technology: The Future of Photovoltaics

Heterojunction Technology (HJT) represents the forefront of solar cell innovation, combining the best attributes of crystalline silicon and thin-film technologies. With cutting-edge designs like 0BB (Zero Busbar) and HBC (Heterojunction with Back Contact), HJT solar cells offer superior performance, high efficiency, and long-term reliability.

Key advancements include the 0BB approach, which eliminates traditional busbars, resulting in higher energy conversion and reduced material costs. The HBC technology shifts electrical contacts to the back of the cell, maximizing front-side light absorption and pushing efficiency even further. Additionally, perovskite-HJT tandem cells are pushing the boundaries of efficiency by reaching over 30% in lab conditions.

HJT cells offer unmatched resistance to LID (Light-Induced Degradation) and PID (Potential-Induced Degradation), ensuring long-lasting performance. Their bifaciality (up to 90%) allows energy collection from both sides, making them ideal for various installations, while the low temperature coefficient (-0.24%/°C) ensures minimal efficiency losses in high temperatures.

With these technological advantages, HJT is set to shape the future of solar energy, offering a sustainable, efficient, and scalable solution to meet global energy demands. Explore more about HJT’s cutting-edge technology on HJTpv.com.

Conclusions for HJT

HJT technology, with its variations in 0BB, HBC, and tandem perovskite cells, stands out due to its superior efficiency, high bifaciality, minimal degradation, and exceptional performance under various conditions, including low-light scenarios. The low temperature coefficient, resistance to PID and LID, and effective utilization of both sides of the cells position HJT as a leading technology in the photovoltaic industry, outperforming alternatives like TOPCon in terms of long-term durability, energy production, and overall efficiency.