Innovative technology of combined plant cultivation and energy production electricity using photovoltaic solutions

The system will simultaneously fulfill the following functionalities, meeting identified market needs:

- the possibility of combining modules into segments with power adapted to the needs of the farm,

- reducing maintenance costs by reducing theconsumption of electricity from the network,

- incorporating an irrigation system powered by solar/wind energy into the crop,

- reducing the demand for water needed for irrigation,

- protection of plants against storms of rain, hail and bright sun,

- off-grid and UPS emergency power supply.

Agri PV system features

The system is compatible with the development of the SMART GRID strategy and distributed systems using energy storage. In the option with energy storage, an off-grid system with a UPS option is possible.

It is also possible to add EV chargers for electric agricultural machines.

The system can be adapted, including wind turbines as an additional generation source.

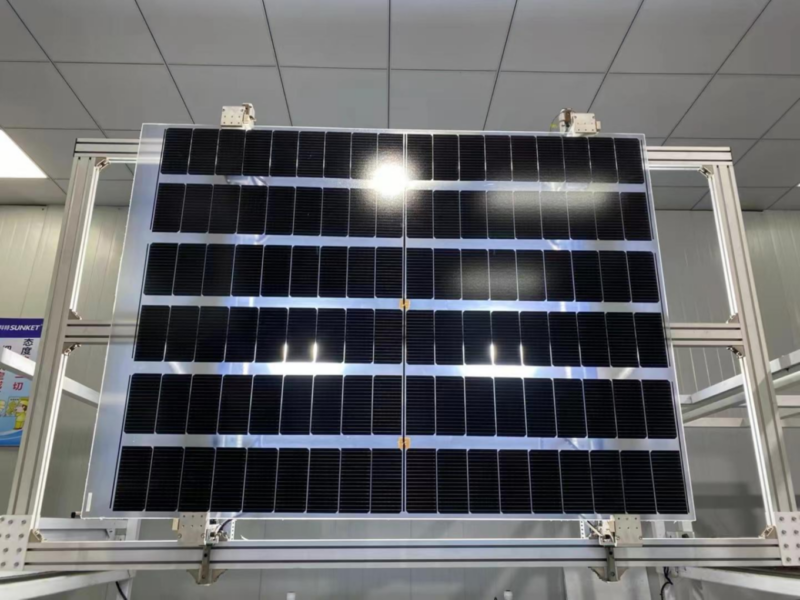

Mysolar HJT AgriPV panels

The use of the largest modules on the market allows for:

- Protection of plants from the sun, heavy rain and hail,

- Collecting the maximum amount of water from rainfall,

- Combination of AgriPV modules in the same size standard (400W-700W) with the most powerful 720W modules.

Why HJT modules are a reasonable choice for solar farms?

Heterojunction (HJT) is a solar cell technology that has several advantages that make it a good choice for solar farms.

Higher efficiency: HJT cells can achieve higher conversion efficiencies than traditional silicon cells, meaning they can convert more sunlight into electricity. This can lead to a larger amount of power generated from each panel, which can help to reduce the cost of a solar farm project. The most powerful HJT serial produced module 720W has 23,17% efficiency.

Improved temperature performance: HJT cells are less sensitive to temperature changes than traditional silicon cells, which means they can continue to generate electricity at a high efficiency even in hot weather. This can be a major advantage in regions with hot climates, where traditional silicon cells can lose efficiency as temperatures rise. Temperature coefficient 0,24%-0,26% compared to 0,3% in TopCon and 0,35-0,4% in PERC give a visible difference in power production.

Greater durability: HJT cells are also more durable than traditional silicon cells, which can help to extend the lifespan of a solar farm. They are less likely to be damaged by harsh weather conditions or environmental pollutants.

Reduced manufacturing costs: HJT cells are manufactured using a more efficient process than traditional silicon cells, which can help to reduce the cost of production. This can make HJT cells a more cost-effective option for solar farms, especially as the technology continues to mature and production costs fall. Due to the fewer production steps compared to PERC and TopCon and the low temperature needed to produce HJT carbon footprint in the case of HJT modules is lower.

Overall, HJT is a promising solar cell technology that has the potential to revolutionize the solar industry. Its higher efficiency, improved temperature performance, greater durability, and reduced manufacturing costs make it a good choice for solar farms.

HJT Technology in Agri Sector

The choice of bifacial panels in HJT technology with G12 (210mm) Half-Cut cells is the optimal solution for the project due to the possibility of producing energy from both sides of the photovoltaic module. Due to the choice of HJT cell production technology, the “Bifacial” parameter, i.e. the power generated from Albedo reflection, is up to 95%.

Compared to PERC 70% and TopCon up to 85% photovoltaic panels, it is currently the best possible choice in terms of double-sided energy production from a photovoltaic panel.

Double-sided panels also have a solar glass cover on both the upper and lower sides of the photovoltaic module, which affects:

- limiting the fire by more than 95% compared to non-bifacial plastic panels without double glass shelter,

- reduces degradation and allows you to estimate the life of a photovoltaic panel in HJT technology up to at least 30 years,

- resistance to salt mist and ammonia,

- in rural conditions, it protects the photovoltaic panel against dust, dirt and damage.

cell efficiency >27% and solar panels >23.82%,

lowest temperature coefficient -0.24%/°C.

The temperature coefficient is an extremely important parameter in the operation of photovoltaic panels. Nominal power values are only laboratory indicators for the 25 degrees Celsius at which the tested photovoltaic panels operate. In field conditions, with high sunlight and no wind, photovoltaic modules can reach temperatures of up to 60 °C. Thanks to the lowest temperature coefficient in the entire photovoltaic industry, HJT panels lose the least power with each degree Celsius. For comparison, PERC technology is -0.4%/°C and TopCon is between 0.3%-0.4%/°C.

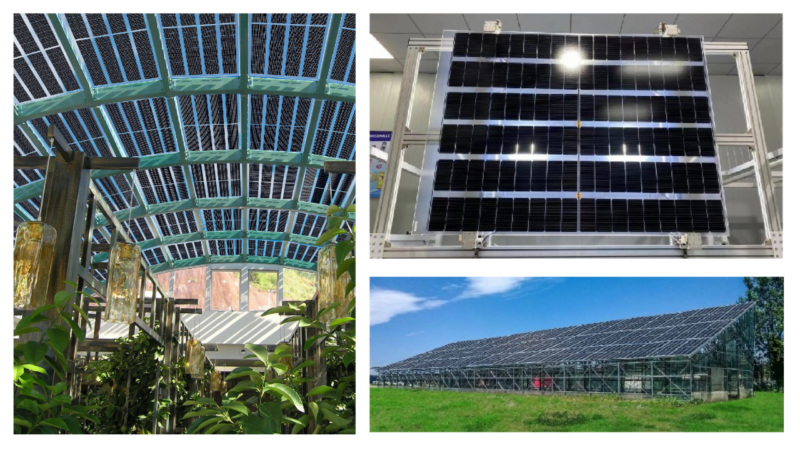

The modular construction Energia Pomorze consists of autonomous sections

Currently, the maximum assumption for the system is:

structure of the shelter on a grid of 10 x 10 m poles. Individual segments have a gable system with an inclination angle of 10°. The clear height (passage) is 4.0 m. The height at the ridge is 5.30 m.

Individual ENSON design assumptions allow for dedicated:

support spacing, e.g. 5 x 5 m,

lower positioning of the sheathing made of panels, e.g. 2 m,

any configuration of panels and their power, e.g. from 5% to 42% transparency and power from 400W to 720W/730W.

AgriPV system with transparent solar panels with patented technology V shape.

Main features:

1. Electricity Production

The system uses transparent PV modules in TOPCon or HJT technology. By transmitting part of the photosynthetic light, the installation supplies the farm with clean energy, and in large-scale projects it also allows for the sale of surpluses. The energy generated on site reduces dependence on the grid and stabilizes costs, while supporting decarbonization goals.

2. Water collection and retention

Profiled gutters drain rainwater into slender tanks in the column axis. The collected water supplies drip irrigation lines, limits surface runoff and increases soil moisture during periods of drought. Retention acts as a buffer – plants go through critical weeks. Possibility of supplying the system, e.g., from a deep intake.

3. Support for Agricultural Production

The controlled shade created by the V-shaped arrangement moderates extreme temperatures and reduces evaporation, which promotes a healthier microclimate and more even crop ripening. The design based on screwed steel anchors does not introduce concrete, so the character of the soil remains intact, and the 4 m clearance allows free passage of any cultivation machine.

More info about it www.agripv.systems

Assumptions for the use of a corrosion-resistant structure with a Magnelis® coating

In order to ensure proper anti-corrosion protection, ENSON ground-based photovoltaic structures are made of steel covered with a Magnelis® metallic coating. The coating is much more resistant to corrosion than galvanized products. The innovative coating guarantees long-term protection against corrosion in aggressive environmental conditions up to corrosion class C5, which translates into increased service life of photovoltaic installations.

Magnelis® is the most effective solution used in harsh environmental conditions containing chlorides and ammonia. Moreover, this coating creates a compact protective layer even in places subjected to bending, stamping or profiling processes.

Energia Pomorze Section example

Optional installation of a water collection system with an irrigation and panel washing system.

The irrigation system depends on the characteristics of the plants grown in the project or the assumptions of water retention and its secondary use.

Ampio System control and regulation

The main advantage of command and control is the distributed system, which is characterized by the lack of a central control device. The system configuration is distributed among the individual devices it concerns. Therefore, when one of the control modules or sensors is damaged, the rest of the installation works as intended.

This translates into:

Resource sharing: a distributed system can share hardware, software or data,

Concurrent processing: the ability to process multiple tasks simultaneously,

Openness: the possibility of expanding the system. This is a very important element when expanding the system with automation of a farm, processing plant or energy elements such as energy storage and EV charging stations,

Concurrency: users can assign multiple tasks to the system at the same time,

Scalability: allows you to maintain similar system performance while increasing its scale and expanding the system,

Failure tolerance: a failure of one element means that only one element is faulty, the rest of the system works properly.

The control system is an open system, which allows for expansion and integration with:

energy storage units (most of them communicate in CAN),

industrial and building automation systems,

SCADA systems for energy management on the network and user side,

the possibility of combining generation sources, energy storage and energy consumption elements such as machines, devices, lighting or heating.

The control and control system allows you to create SMART GRID.

An intelligent network based on the system allows the integration of AgriPV modules among themselves, creating an integrated network in one control infrastructure. Assuming automation of a farm, production or processing company using AMPIO, we get our own intelligent network managed in one system based on many parameters and factors. Based on the farm’s consumption, it is possible to use renewable energy from the project. Weather prediction models, weather stations and sensors will allow you to automate and optimize production processes and energy consumption.

Using the project as an element of a distributed energy strategy (independent energy source)

The system allows for:

integrate individual AgroPV modules into groups,

create off-grid systems for agricultural and agri-processing farms,

create energy collectives,

take advantage of cable pooling.

It is also possible to connect to energy storage, power wind turbines, EV chargers or hydrogen production.

Energy Storage Systems and Implementation

The AgroPV system has the ability to integrate with energy storage units, which will be designed and supplied under the cooperation. The basic battery module is a 20 ft. liquid-cooled container with a capacity of 5MWh and 3.4 MW. The container sections can be scaled to meet any design intent.

Special abilities in heterojunction technology for utility projects.

HJT cells an modules are particularly well-suited for bifacial modules due to their lower internal resistance and improved light-trapping capabilities. This allows bifacial HJT modules to generate more electricity from both the front and back of the panel, further enhancing their overall output (up to 95% light from albedo reflection).

Here are some specific benefits of HJT technology in bifacial modules:

Enhanced Power Output: Bifacial HJT modules can achieve higher power outputs compared to traditional bifacial modules due to the higher efficiency of HJT cells. This can lead to significant increases in energy production for solar farms. Most powerful 720W power solar panels.

Improved Light Trapping: HJT cells have an advanced surface texture that helps to trap more sunlight, resulting in better light absorption and increased power generation.

Lower Internal Resistance: HJT cells have a lower internal resistance, which allows them to dissipate heat more effectively and maintain their efficiency under high-power conditions. This is particularly important for bifacial modules, which are exposed to more heat due to their dual-sided light collection.

As a result of these advantages, bifacial HJT modules are becoming increasingly popular for solar farms seeking to maximize their energy production and optimize their return on investment.

Here’s a table summarizing the key benefits of HJT technology for bifacial modules:

| Feature | Traditional Bifacial Modules | Bifacial HJT Modules |

|---|---|---|

| Power Output | Lower | Higher |

| Light Trapping | Less Effective | More Effective |

| Internal Resistance | Higher | Lower |

| Heat Dissipation | Less Efficient | More Efficient |

| Overall Energy Production | Lower | Higher |

Overall, HJT technology is a promising advancement in solar cell technology that can offer significant benefits for bifacial modules, particularly in terms of power output, light trapping, internal resistance, and heat dissipation. These improvements can lead to increased energy production, improved system reliability, and extended lifespan for solar farms.

Why HJT prevent LID and PID influence?

HJT technology is inherently less susceptible to PID and LID than traditional silicon solar cells. This is due to the unique structure of HJT cells, which have a thin amorphous silicon layer sandwiched between a high-quality crystalline silicon wafer and a passivating layer. This structure helps to prevent the formation of electrical fields that can cause PID, and it also reduces the amount of light-induced damage that can lead to LID.

Preventing PID:

PID occurs when electrical fields induced by other components in the solar panel’s electrical system cause the degradation of the front contact of the solar cell. HJT cells are less susceptible to PID because the thin amorphous silicon layer acts as a barrier to these electrical fields, preventing them from reaching the front contact.

Reducing LID:

LID is a temporary decrease in the efficiency of solar cells that occurs when they are exposed to high-intensity light. HJT cells are less susceptible to LID because the passivating layer helps to protect the solar cells from these harmful light rays.

As a result of its resistance to PID and LID, HJT technology can help to ensure the long-term performance and reliability of solar panels, particularly in harsh environments or when operating in an interconnected solar farm. This can lead to increased energy production and a lower overall cost of ownership for solar farms.

Here’s a table summarizing the key benefits of HJT technology in terms of PID and LID mitigation:

| Feature | Traditional Silicon Cells | HJT Cells |

|---|---|---|

| Susceptibility to PID | High | Low |

| Susceptibility to LID | High | Low |

| Long-term Performance | Shorter | Longer |

| Reliability | Lower | Higher |

Overall, HJT technology’s resistance to PID and LID can significantly contribute to the long-term performance and reliability of solar farms, making it a more attractive option for investors and project developers.

The amorphous silicon layer in HJT cells plays a crucial role in enhancing their power output and overall efficiency. Here’s how it contributes to increased power production:

Surface Passivation: The amorphous silicon layer serves as a highly resistive layer that effectively passivates the silicon surface, preventing the formation of surface defects and recombination centers. These defects can trap electrons and holes, reducing the solar cell’s ability to generate electricity. By passivating the surface, the amorphous silicon layer allows more light to be absorbed and converted into electricity.

Light Trapping: The amorphous silicon layer acts as a waveguide, trapping light within the cell and enhancing light absorption. This is achieved through the creation of a graded index of refraction, which guides light rays through the cell and maximizes their interaction with the silicon material. This improved light trapping capability leads to a higher conversion efficiency and more power generation.

Reduced Shock Degradation: The amorphous silicon layer protects the silicon wafer from mechanical stress and shock-induced degradation. This is particularly important for bifacial modules, which are more prone to stress due to their dual-sided light collection. By minimizing shock damage, the amorphous silicon layer ensures the long-term stability and performance of the solar cell.

Enhanced Stability: The amorphous silicon layer exhibits excellent thermal stability, maintaining its properties even under harsh environmental conditions. This stability is crucial for long-term performance as solar cells operate under varying temperatures and climatic conditions.

Improved Lifetime: By mitigating surface defects, reducing shock damage, and maintaining stability, the amorphous silicon layer contributes to the overall lifetime of the HJT cell. This extended lifetime translates to more years of power generation and a lower cost of ownership for solar farms.

In summary, the amorphous silicon layer in HJT cells plays a vital role in enhancing power output, improving surface passivation, facilitating light trapping, reducing shock degradation, enhancing stability, and extending lifetime. These advantages make HJT technology a promising and efficient solution for solar farms, contributing to increased energy production, improved system reliability, and extended lifespan.