- HJTPV.com

- HJT Technology

- HJT Producers

- HJT Solar Panels

- HJT Solar Panel Mysolar Gold 740W

- HJT Solar Panel Mysolar Gold 640W

- HJT Solar Panel AEsolar COMET 720W

- HJT Solar Panel AESOLAR COMET 650W

- HJT Solar Panel Bi Chaser Akcome 120 Cells

- HJT Solar Panel HuaSun HS-B120DS

- HJT Solar Panel Jinergy JNHM120 Cells

- HJT Solar Panel Risen Hyper-ion

- HJT Solar Panel QW Solar Giwa5 730W

- HJT Solar Panel QW Solar Giwa5 640W

- HJT Solar Panel Risen RSM120

- Cleaning Robot

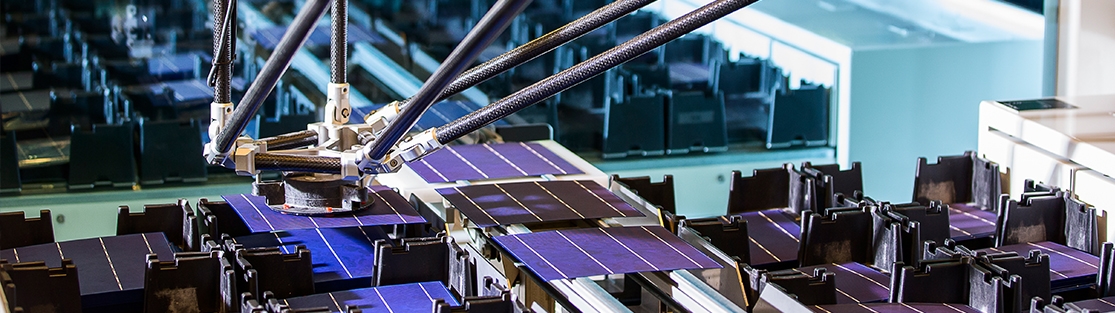

- HJT Solar CELLS

- News&Knowledge

- Contact

- HJTPV.com

- HJT Technology

- HJT Producers

- HJT Solar Panels

- HJT Solar Panel Mysolar Gold 740W

- HJT Solar Panel Mysolar Gold 640W

- HJT Solar Panel AEsolar COMET 720W

- HJT Solar Panel AESOLAR COMET 650W

- HJT Solar Panel Bi Chaser Akcome 120 Cells

- HJT Solar Panel HuaSun HS-B120DS

- HJT Solar Panel Jinergy JNHM120 Cells

- HJT Solar Panel Risen Hyper-ion

- HJT Solar Panel QW Solar Giwa5 730W

- HJT Solar Panel QW Solar Giwa5 640W

- HJT Solar Panel Risen RSM120

- Cleaning Robot

- HJT Solar CELLS

- News&Knowledge

- Contact

Part of HJT Technology

Glass-Glass Technology

On this Site You Will Read About

Explore the Experts

Double Glass Technology in PV

Glass-glass module structures (Glass Glass or Double Glass) is a technology that uses a glass layer on the back of the modules instead of the traditional polymer backsheet. Originally double-glass solar panels were heavy and expensive, allowing the lighter polymer backing panels to gain most of the market share. Thanks to producers such as:

- AKCOME

- Jinergy

- Jolywood

- Risen,

glass-glass is making a comeback, based on an increase in the market share of bifacial modules and an increase in the number of PV installations on a business scale and solar farms preferring more durable module designs such as glass-glass.

Double glass solar panels

Double-glazed modules are characterized by increased reliability, especially for large-scale photovoltaic projects. They include better resistance to higher temperatures, humidity and UV conditions, and have better mechanical stability, reducing the risk of microcracks during installation and operation. Double Glass is especially important in photovoltaic facilities such as solar power plants and with the expected long service life of modules such as AKCOME, Jinergy or Jolywood.

Why solar panels with glass-glassTechnology?

Best Performance

Highest Efficiency and power of solar panels

Long Warranty

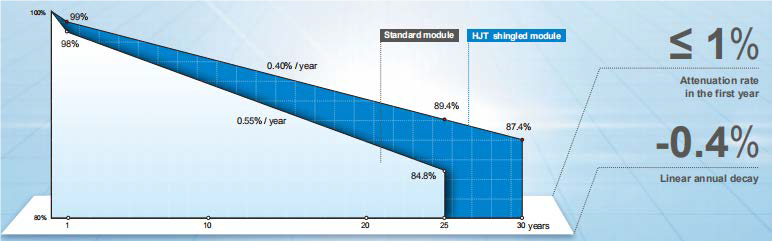

30 years with only 0,4% annual degradation

inspiring technology

N-type Bifacial Cells cover in Glass glass frame

Why is solar double glass more durable?

An important change that has been made in the case of Glass-Glass modules is the replacement of EVA with polyolefins as an encapsulating substance. This is due to the free radicals generated during the EVA cross-link lamination process. While traditional backsheets are somewhat permeable to free radicals, the double glass module is not. The same can be said for moisture that can seep in from the sides of the module and get trapped in the double-glazed structure. Therefore, the impermeability of these degrading agents is a major argument against glass-to-glass as it traps both free radicals and moisture inside the module, potentially shortening its field life. The issue of trapped moisture is actually the main argument against double glass modules. Polyolefins are used as encapsulating substances, which solves the problem of free radicals and the problem of moisture is solved by the execution, which is confirmed by e.g. PVEL tests.

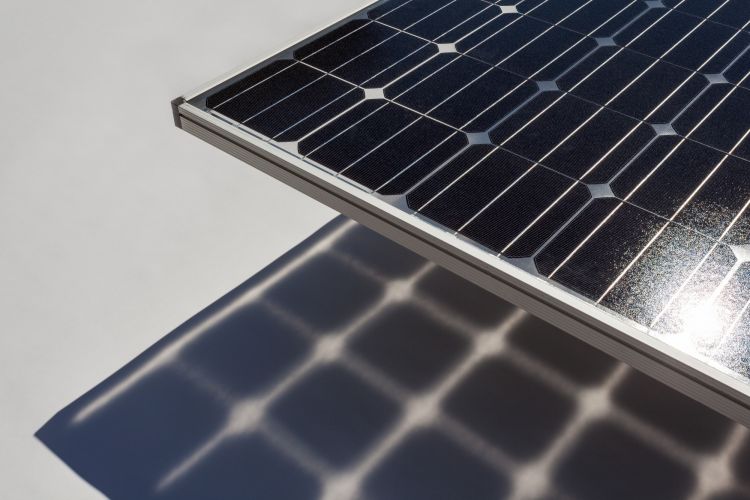

How looks Glass Glass Panels?

Utility Scale Glass Glass Modules

Double glass solar panels

Double-glass modules are characterized by increased reliability, especially for large-scale photovoltaic projects. They include better resistance to higher temperatures, humidity and UV conditions, and have better mechanical stability, reducing the risk of microcracks during installation and operation. Double Glass is especially important in photovoltaic facilities such as solar power plants and with the expected long service life of modules such as AKCOME, Jinergy or Jolywood.

Glass-Glass for the PV Farm?

Due to the increased reliability of the double glazing unit design, they are expected to degrade only 0.4% per year on average, as opposed to the traditional polymer back layer at 0.7% per year. Therefore. over 30 years of operation, it can be expected to continue to operate at 85% of the rated power (some modules already reach over 87% after 30 years).

What Double Glass Technology offer

Glass-Glass Advantage

Rear Side Module Protection

Highest Fire Resistance

Glass Glass COVER

Bifacial POWER

Lowest Degradation

strength and durability

state-of-the-art Solar Solution

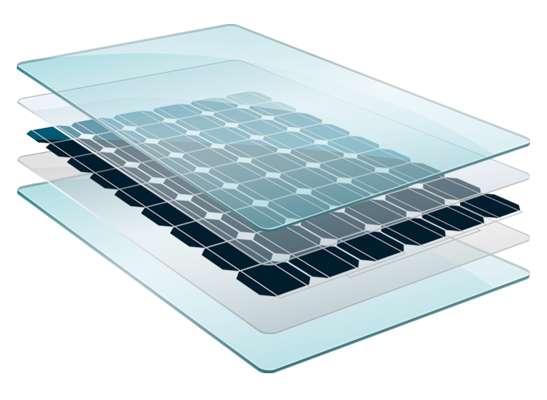

How is construct Glass Glass Panel?

What is a double-sided solar module?

Double-sided modules generate solar energy from both sides of the panel. While traditional panels with an opaque back coating are single-phase, the bifacial modules reveal both the front and back sides of the solar cells. When bifacial modules are installed on a highly reflective surface (such as a white roof or on the ground with light stones), manufacturers of double-sided modules say production is increased by up to 30% only due to the extra power generated from the rear. Bifacial modules are available in many versions. Some are framed and some are frameless. Some are made of double glass and others have transparent pads. Most manufacturers use monocrystalline cells, but polycrystalline designs exist. The only thing that is constant is that power is generated from both sides. There are frameless double glass modules that reveal the back side of the cells, but are not double-sided. True bifacial solar panel have contacts / busbars on both the front and rear of the cells.

Bifacial Modules Future?

What are the perspectives for bifacial modules? The challenge with bifiacial design has always been the unpredictability of power output as it depends on the ground behind the modules - white commercial roof, dark tile, grass and gravel. It is difficult to model and estimate the productivity of double-sided PV modules. Bifacial modules do not differ from the competition in terms of costs, which means that the investment costs, even with some additional production, drop. The Chinese solar panels producers like Akcome, Jinergy or Risen believes that we are entering a new era of photovoltaics, in which high-efficiency modules are paramount. The bifacial technology supports the concept of using high-quality materials to achieve high energy efficiency. Bifacial modules are probably the future of the industry. Double-sided PV modules inherit all the advantages of mono PERC modules: high power density resulting in significant BOS savings, high energy yield with better performance in low light and lower temperature coefficient. In addition, double-sided PERC modules also collect energy from the rear side, showing a higher energy yield.

Why choose Glass-Glass Panels?

Double Glass Technology Profits

Why Glass Glass Panels Are The Best?

Best Advantage of Double Glass Solar Panels

Explore the Experts

Best Double Glass Module Producers

Risen

Jolywood

commit to HJT Solar Revolution

Glass-Glass Solar Panel- best Solution for Utility scale investitions?

Long warranty for power production >30 Years

Highest Efficiency >22%

Low Yearly degradation, only >0,4%

Best Bifiaciality efficiency >85%

Lowest Temperature Coefficient 0,24%-026%/°C

Very low modules failure risk factor

All You Need To Know About Double glass Technology

frequently asked questions

HJT(ntype) bifacial efficiency can achieve even 27%. But usually producers like Acome and Jinergy use Heterojunction solar cells with 24%-25% efficiency. Compare to PERC Cell, HJT can achieve even 20% more power.

Bifacial HJT solar panels have the best efficiency in serial production. Scope of it is between 21%-22,5% with R&D plan even to 26%. N-type module has the best performance and most reliable characteristic resistance for most common fail from all over solar technology.

HJT with N-type technology solar Panels with 120 cells have a scope of power between 370W-390W and for 144 cells 425W – 470W. At the end of 2021 Power of HJT modules will achieve >500W and in soon future will be >600W.

N-type Bifacial technology ensures a long safe warranty for 30 years of production and 12 -20 years for a panel, depends on the producers. It’s more approx. 5 years than common PERC panels.

Bifacial HJT solar panels with N-type cells are value for money solutions. Compare with standard backsheet modules, the price for Heterojunction is a little bit more. But compared with Bifacial, glass-glass solar panels, HJT is the best solution and has more advantages worth a few % higher price.

Higher power, bifaciality, efficient production under extreme conditions, combined with the world’s lowest degradation, no LID and PID effects and a double glass structure (GLASS-GLASS), allows you to generate significant savings over 30 years of use compared to PERC panels.

Glass is the best protection for the silicon cells that are the heart of the photovoltaic module. A cell is a unit that generates electricity, but it is made of a delicate material that needs to be reinforced and secured externally. For this purpose, we have a good ally in the form of solar glass, which, in addition to being transparent, is an electrical insulator.

HJT PV team is not only a trusted advisor but solar panels broker. We are helping Clients from all over the world connect to trusted and checked HJT producers. Direct cooperation ensures the best prices and fast delivery, to all destinations.

Glass-Glass Solar Panels Sales and distribution

EPC Cooperation

general contractor of photovoltaic investments

Distributor In Europe

Container and Mega Watt sales

Photovoltaic Broker

mediation in the purchase directly from the manufacturer