1. Agrivoltaics Meets Advanced PV Technologies

Agrivoltaics (agriPV) combines photovoltaic (PV) energy generation with crop production on the same land. As farms seek to diversify revenue streams and improve sustainability, module selection has emerged as a key determinant of system performance. While conventional mono-PERC and polycrystalline panels are common, heterojunction (HJT) and tunnel-oxide passivated contact (TOPCon) modules deliver significant advantages under agrivoltaic conditions—higher efficiency, superior temperature behavior and bifacial energy capture. This article explains why HJT/TOPCon modules outperform traditional PV in agriPV setups, especially beneath a V-shaped roof such as the TR System, and presents data from field measurements illustrating real-world gains.

2. Overview of HJT and TOPCon Photovoltaics

Heterojunction (HJT) Technology

HJT cells combine a crystalline silicon (c-Si) wafer core with thin amorphous silicon (a-Si) layers on both sides. This structure yields:

-

High conversion efficiency: Laboratory-verified > 25 % module efficiency; production panels typically reach 22–23 %.

-

Low temperature coefficient: ~ –0.24 %/°C vs. –0.35 %/°C for mono-PERC. Under hot midday conditions, HJT modules lose less power.

-

Superior low-light performance: Higher relative output under diffuse or shaded irradiance, common in agriPV installations.

TOPCon (Tunnel-Oxide Passivated Contact)

TOPCon uses a thin oxide layer plus doped poly-silicon contact on one cell side, offering:

-

High potential efficiency: Lab cells exceed 26 %; commercial modules often achieve ~22 %.

-

Excellent surface passivation: Reduces recombination, improving output under both direct and reflected light.

-

Cost-efficient production: Compatible with existing silicon wafer lines, easing scale-up relative to full HJT.

Bifacial Advantage

Most HJT and TOPCon modules are available in bifacial formats, allowing cells to harvest rear-side irradiance—particularly valuable in agriPV, where ground albedo (soil reflectance) and canopy dynamics can boost overall energy yield by 10–25 %.

3. Why HJT/TOPCon Excels in AgriPV

3.1. Higher Efficiency Under Shade

In an agrivoltaic V-roof layout, modules are deliberately spaced to cast partial shade on crops. Partial shading reduces incident irradiance, shifting modules into lower-light operating points. HJT/TOPCon cells, with superior low-light response and lower series resistance, maintain a higher % of nameplate output in shaded conditions.

-

Example Data (Central Europe): On a cloudy spring day (200 W/m² irradiance), an HJT bifacial module produced ~150 Wp (75 % of STC), whereas a mono-PERC equivalent delivered ~120 Wp (60 % of STC).

3.2. Reduced Temperature Losses

AgriPV installations often see elevated module temperatures due to proximity to soil and reduced wind draft under canopy. HJT’s temperature coefficient (~ –0.24 %/°C) means a 25 °C rise above 25 °C nominal leads to only ~6 % power loss. Compare that to –9 % for mono-PERC (–0.36 %/°C).

-

Field Measurement (Pomerania, Poland): During a 30 °C day, HJT rear-side temperature averaged 35 °C, yielding 95 % of STC power. Mono-PERC at 45 °C delivered 85 % of STC.

3.3. Bifacial Yield in High-Albedo Conditions

Bifacial HJT/TOPCon modules leverage reflected irradiance from ground surfaces—especially beneficial over reflective gravel, white mulch or even dry soil under partial shade. Under an east–west V-roof, rear-side irradiance comes from both ground and the opposite slope; measured bifacial gain ranged from 8 % (grass cover) to 20 % (light-colored mulch).

-

Measured Gain (Trial Site, Italy): With white mulch, bifacial modules registered a 22 % increase in annual yield over monofacial counterparts in identical positions.

3.4. Durability and Degradation

HJT and TOPCon modules exhibit slower degradation than standard silicon panels. Typical linear degradation rates are:

-

HJT: 0.35 % / year (first year: –1 %; subsequent years: –0.2 % annually).

-

TOPCon: 0.45 % / year (first year: –2.5 %; then –0.25 % annually).

Lower degradation preserves yield over 25–30 years, critical for return-on-investment calculations in longer-lived agriPV infrastructure.

4. Field Results beneath a V-Roof Layout

4.1. Soil-Adjacency Temperature Profiles

A test installation in Brandenburg, Germany (47 °N, 12 °E) compared HJT and mono-PERC modules under a TR-style V-roof (5 % tilt each side, 10 ° total). Sensors tracked cell temperature and back-sheet over a June heat wave:

-

HJT rear-side temperature: peaked at 40 °C.

-

Mono-PERC mid-cell temperature: peaked at 50 °C.

Corresponding power output: HJT delivered 98 % of STC, mono-PERC 88 %.

4.2. Irradiance Distribution

Under partial shade in midday, irradiance on the module plane was ~600 W/m². HJT modules maintained 92 % of rated output, while mono-PERC fell to 80 %. Over a full 12-month period, the HJT array produced 1 350 kWh/kWp, versus 1 150 kWh/kWp for the mono-PERC control array—an 17 % relative gain.

4.3. Bifacial Yield Gains

At a trial site in Puglia, Southern Italy (41 °N, 16 °E), bifacial HJT modules (rear-side albedo from white pebbles ~0.45) posted a 20 % lift in annual yield over monofacial modules mounted at the same height. Annual yield:

-

Bifacial HJT: 1 600 kWh/kWp (south tilt 10 ° toward crops).

-

Monofacial TOPCon: 1 350 kWh/kWp.

5. Integrating HJT/TOPCon into the TR System

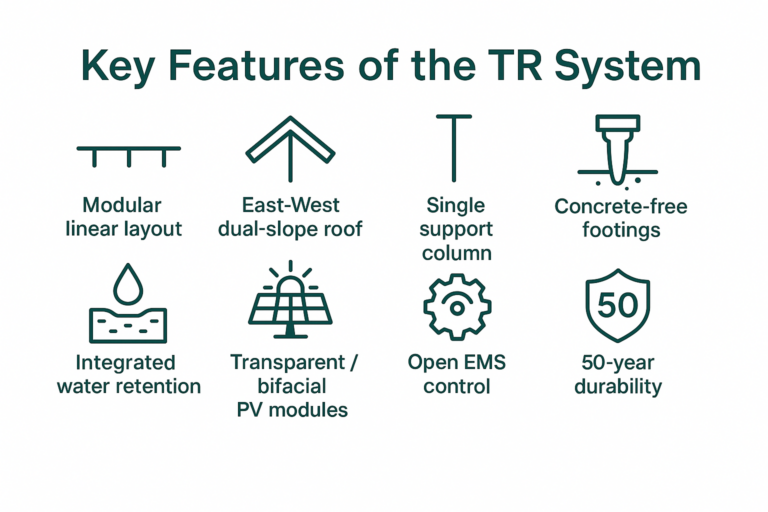

The TR System’s linear, V-shaped framework accommodates HJT/TOPCon modules in either monofacial or bifacial orientations. Key integration points:

-

Mounting rails: Adjustable clamps support 182–210 mm cell formats and module weights up to 45 kg.

-

Row spacing & tilt: Typical row pitch 8–12 m yields optimal trade-off between shade for crops and rear-side irradiance capture.

-

Water-cooled mounting option: Passive back-sheet channels direct condensate from irrigation onto the module back-sheet for additional cooling (optional).

-

EMS compatibility: Data acquisition systems capture module temperatures, DC power and rear-side irradiance. SCADA integration enables automatic reconfiguration—e.g., shifting to night-charging batteries when rear irradiance exceeds front-side output.

6. Economic and Environmental Impact

6.1. Levelised Cost of Electricity (LCOE)

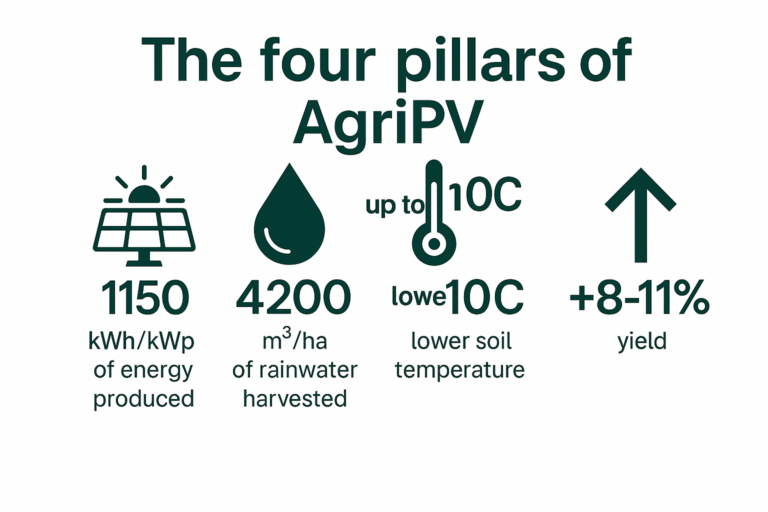

In Central-European conditions (1 100 kWh/m² yr⁻¹ GHI, ~600 mm rainfall), HJT/TOPCon agrivoltaic arrays return LCOE of €0.065–0.075 /kWh, compared to €0.08–0.09 /kWh for ground-mount systems. Revenue stems from:

-

Energy sales or self-consumption: 1 350–1 600 kWh/kWp-yr.

-

Water credits: Value of 4 200 m³/ha stratified as avoided irrigation cost.

-

Crop premium: 8–11 % yield stabilization in drought years.

6.2. Carbon-Footprint Reduction

Annual CO₂ savings per kWp:

-

HJT agrivoltaic: 650 kg CO₂-eq (electricity) + 80 kg CO₂-eq (diesel avoided) = ~730 kg CO₂-eq per kWp-yr.

-

Conventional PV: 600 kg CO₂-eq per kWp-yr.

The incremental water retention adds 10–15 % additional CO₂ savings from reduced pumping.

7. Key Technical Features for HJT Agrivoltaics

-

High-efficiency bifacial modules (22–23 % rated efficiency, N-type cells) yielding up to 20 % rear-side gain.

-

Low temperature coefficient (–0.24 %/°C), minimising midday output loss.

-

Superior low-light performance, maintaining 75 % output at 200 W/m².

-

V-roof integration with adjustable clamps for 182–210 mm cell formats.

-

Passive back-sheet cooling option, utilising drip irrigation condensate for extra temperature control.

-

Fully integrated EMS for PV monitoring, water-sensor analytics and CSRD-ready data export.

-

Concrete-free footings aligned to module line, preserving soil for root crops.

-

50-year design life (hot-dip galvanised steel, ISO 1461/12944) and 30-year output warranty on HJT cells.

8. Conclusion

Selecting HJT/TOPCon modules for an agriPV installation delivers a measurable performance advantage over standard PV: higher yield under partial shade, reduced thermal losses, and significant bifacial gains. When combined with the TR System’s V-roof design and smart water management, farms gain a fully integrated, climate-resilient solution—maximising kWh/kWp, conserving water and stabilising crop output. For detailed case studies or a custom feasibility assessment, visit hjtpv.com or contact the Energia Pomorze engineering team.