CIGS Technology – Introduction

CIGS or “Copper Indium Gallium and Selenide” is a thin solar/photovoltaic cell technology based on the deposition of four elements (copper, indium, gallium, selenide) on a glass substrate. What distinguishes CIGS is, for example, the best spectral response, i.e. the absorption of solar radiation by panels or photovoltaic tiles made in this technology.

Producers and their R&D are of the opinion that silicon products are doing well “on paper” because research is carried out by many centers and the market is saturated with producers of silicon modules. According to the producers, CIGS exceeds silicon in real conditions and gives higher production, which is confirmed by real data collected in practice.

It is the practical application and properties of the CIGS technology that make this solution a perfect fit for the BIPV (Building Integrated Photovoltaics) niche.

Construction of the CIGS Cell

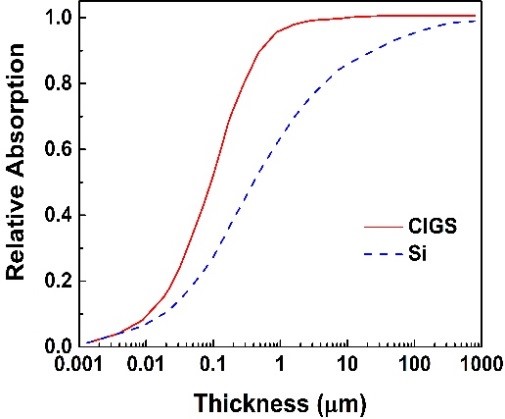

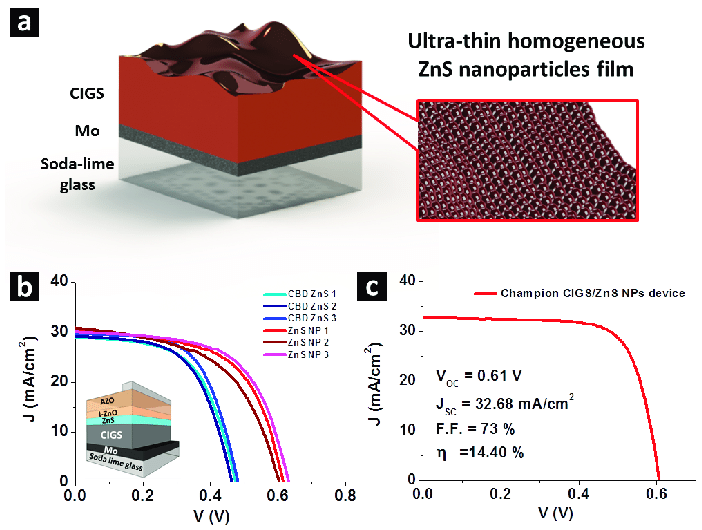

Cu (In, Ga) Se2 (CIGS) solar cells are one of the best-known thin-film technologies, with a record lab efficiency of 23.4% achieved in 2019 by Solar Frontier. The CIGS material has the so-called “Direct BandGap” which means low photon transmittance which results in a high energy absorption coefficient.

Efficient absorption of sunlight can be achieved in CIGS and Thin Layer amorphous silicon layers as thin as 1 µm, as much as 100 times thinner than crystalline silicon solar cells (PERC or TOPCON). An interesting feature of this technology is its high efficiency with the use of less material and the ability to adjust the proportions of individual elements, eg Gallium, for the production of highly efficient photovoltaic cells.

As in PERC cells, the CIGS cell on the underside absorbs energy via the P-Type layer and transfers it via the N-Type CdS (grenocite) layer to the cell surfaces. Hence, the CIGS is made in the p-n junction technology.

Differences between HJT and N-Type, PERC and CIGS

Unlike standard (PERC and N-Type) crystalline solar cells which are homogeneous devices. This means that the p-type and n-type semiconductor layers are formed on the same base material. Heterojunction cells, on the other hand, are made by combining two different types of materials. In the case of HJT silicon, the connection is made between crystalline and amorphous silicon materials.

The heterojunction is formed between an enriched crystalline silicon substrate and an amorphous silicon layer of opposite conductivity (p-type or n-type, respectively).

CIGS, however, as the name suggests, is a combination of 4 elements: copper, indium, gallium and selenide. Thin-Layer, i.e. thin-layer photovoltaic technology (HJT and CIGS), stands in opposition to crystalline silicon, which is mostly made of solar panels.

Solar panel / CIGS tile Construction

CIGS is a thin-film technology that is not based on silicon materials, therefore it has its own special features “

Low sensitivity to shadows, which is especially important in BIPV

High efficiency in harsh conditions thanks to high absorption even in low light

Low-temperature coefficient so high-temperature operation is still efficient

High energy production from different angles

Installation aesthetics

Most importantly, CIGS provides higher yields per kWp installed. This technology enables versatile installations in imperfect conditions such as the building and construction industries. Cells, photovoltaic panels and solar tiles are very durable and definitely aesthetic. It is also one of the non-toxic and safe photovoltaic technologies, which is confirmed, for example, by the RoHS certificate by Eterbright.

Photovoltaic Farm – CIGS Panels and Roof Tiles

In the case of CIGS technology, the profitability and efficiency of the currently offered solutions for photovoltaic farms cannot compete with HJT, TOPCON, or PERC. This does not mean that CIGS in the future, especially in the case of non-standard solutions, will not be competitive in comparison with, for example, HJT solar panels.

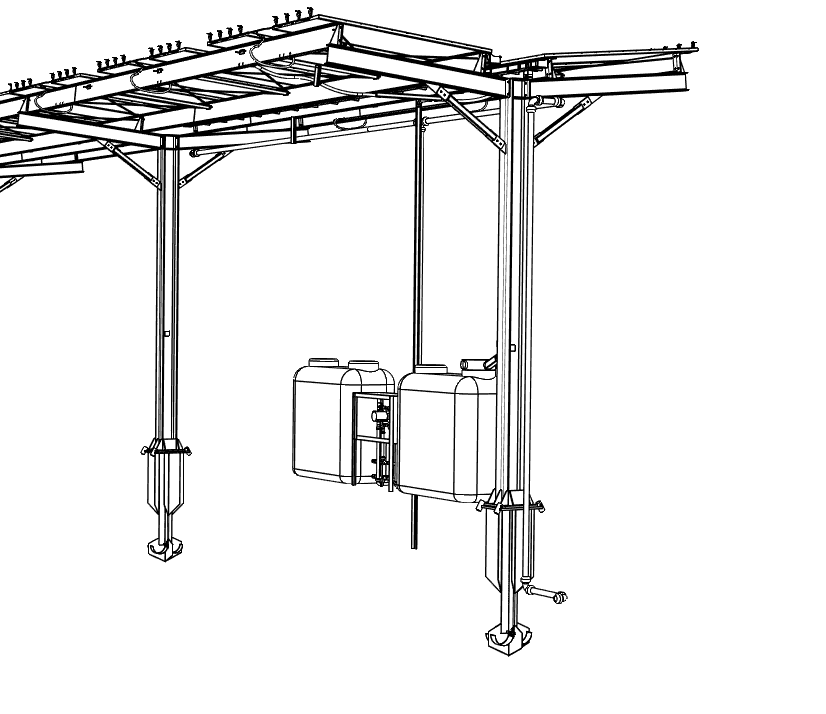

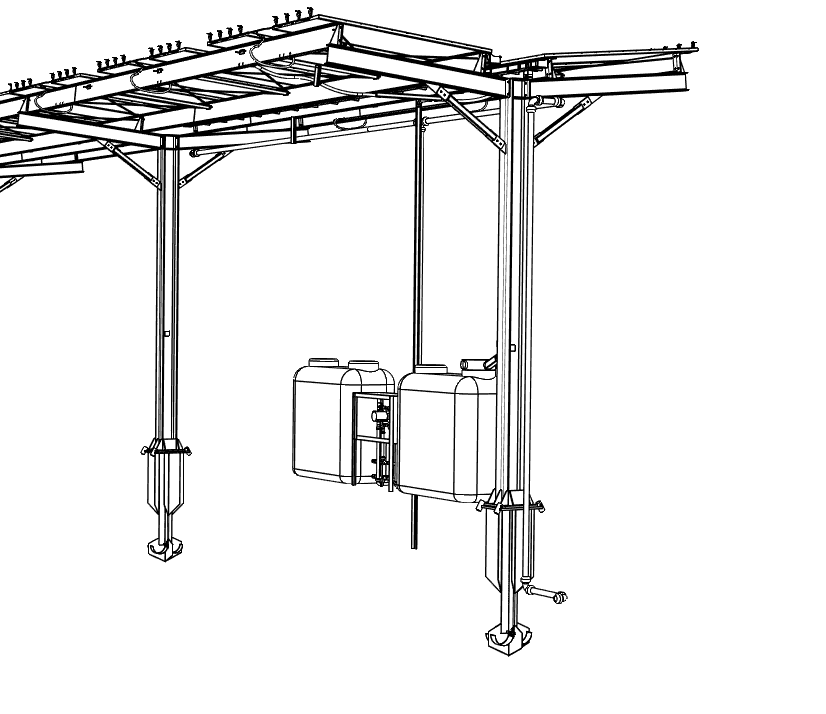

Certainly, the use of this technology is more rational in the BIPV sector. In which today entire buildings generating energy can be created using facade panels and CIGS photovoltaic roof tiles. Thanks to this, thin-film photovoltaics can be used in:

individual buildings with an emphasis on aesthetics and limited roof space

industrial facilities where it is possible to use BIPV elements and large photovoltaic installations> 50kw

construction and construction industry with the use of the entire building area integrated with CIGS panels and tiles.

- Up to 50% more shade production

- Up to 20% better high-temperature performance

- Up to 25% lower service cost (No Hot-Spot)

- Up to 15% higher production, no PID and LID effect

- Aesthetics and ecology thanks to RoHs certification

- Up to 15% more electricity thanks to high absorption

ADVANTAGES AND DISADVANTAGES CIGS TECHNOLOGY

CIGS is solar technology, the reception of which can be extreme depending on the needs and capabilities of individual customers. Certainly, this is not a solution for every investor in photovoltaics due to:

- the relatively higher base cost of the installation,

- very good performance in difficult conditions, where the advantages of CIGS become very visible,

- predisposition to BIPV and construction solutions such as solar tiles

Unlike HJT or PERC, CIGS technology is dedicated to specific segments of the photovoltaic market, as opposed to the above-mentioned technologies that cover the entire spectrum of photovoltaic solutions.

The advantages of CIGS resulting from the construction of photovoltaic cells, panels and roof tiles are:

- durability

- aesthetics

- the flexibility of use in construction (BIPV)

- high performance under difficult or specific conditions

As you can see, thin-film photovoltaic technology goes hand in hand with solutions for energy production integrated with buildings. Therefore, in the case of BIPV, the first choice should be CIGS, e.g. in the form of photovoltaic roof tiles.

High performance under harsh conditions

Properties dedicated to BIPV, in particular, effective work in difficult urban conditions such as:

- cloudy

- shading

- rain

- fog

- polluted air

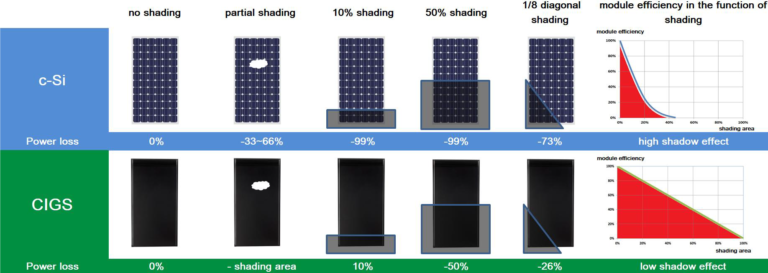

High shade resistance

Unlike silicon, thin-film photovoltaics are relatively insensitive to shading. This means that shadow, dirt or surface damage does not affect the overall production, as is the case with silicon photovoltaic panels. This makes CIGS a very effective solution in integrated urban and industrial photovoltaics.

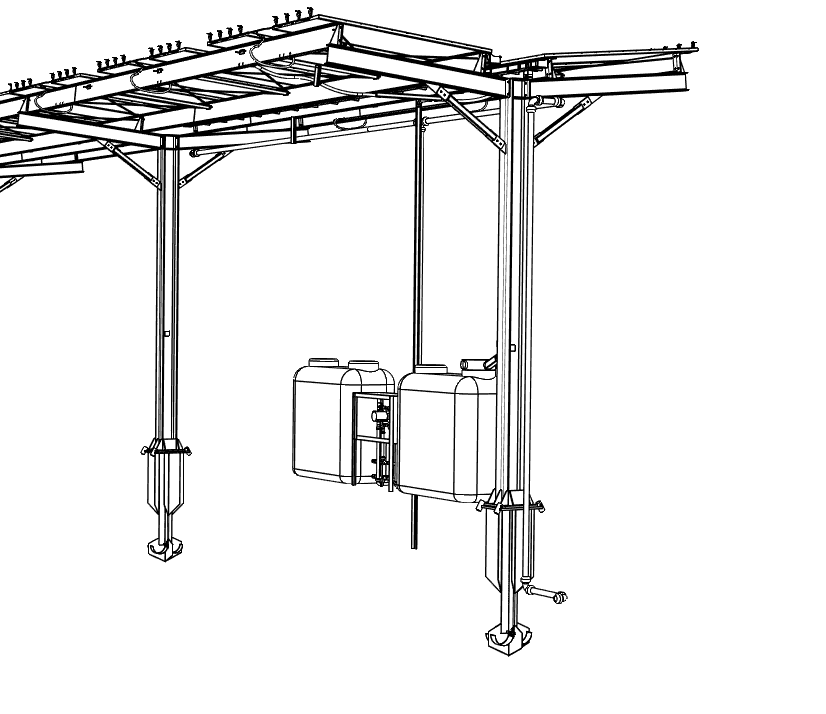

High performance at different angles

CIGS technology allows flexible use of this type of photovoltaic product. Effective and high-performance work at various angles makes the design of buildings, elements of urban or road architecture much easier and aesthetic than in the case of silicon-based products. CIGS will be perfect as:

- building facades

roofs - elements of fences or railings

- sound-absorbing screens

- elements of urban infrastructure

The Best Solar Panels – BIPV?

Like any technology, CIGS has its own set of advantages and challenges. In this case, very good technology, which is unfortunately a niche photovoltaic solution, fights for a larger share of the PV market.

The resultant increase in the presence of CIGS in the world of photovoltaic solutions is BIPV, i.e. photovoltaic solutions integrated with the building. In this field, for example, Eterbright CIGS is doing so well that it can be tempted to point out that it is one of the leading PV technologies. A unique solution, which is a photovoltaic tile, matching standard building and construction solutions for roofs and building facades.

The efficiency of CIGS Technology

Compared to the laboratory, photovoltaic modules and solutions using CIGS technology lose out to HJT or PERC. 19% of practical efficiency (the record is 23.4% according to NREL) with even 23% in the case of HJT, at first glance it is not encouraging. However, the practice and specificity of technological and design solutions mean that CIGS often works better than, for example, PERC panels with higher efficiency. This is for a simple reason, under ideal conditions competing for technologies achieves better nominal results. However, in the long run, in which it is obvious that ideal conditions are sporadic, CIGS turns out to be at least comparable. In difficult conditions such as:

- shadows

- cloudy

- high temperature

- dirt

- photovoltaic panels and tiles (eg Eterbirght) work more efficiently than the competition.

CIGS + Perovskite solar performance record?

The combination of two state-of-the-art “silicon-free” technologies resulted in an efficiency record of 26.5%. This shows both the potential of CIGS and Perovskite, which together provide great opportunities, especially in the BIPV sector.

Reliability of CIGS photovoltaic panels and roof tiles

Facade panels and photovoltaic tiles (manufacturer Eterbright) made in the CIGS technology are characterized by high resistance to external conditions. Due to the lack of LID and PID effects and high resistance to microcracks, the application of this technology in the construction industry does not pose any additional problems. Eterbright photovoltaic roof tiles are snow, wind and hail resistant and installed in accordance with the construction industry standards. Thanks to the imprint of CIGS solar cells on the glass and the very low sensitivity to shading, the risk of hotspots is also very low.

Price of CIGS and BIPV Solutions?

CIGS is highly compatible with the BIPV construction industry. This offsets the higher cost of components such as a solar tile or solar facade panel. By combining PV technology with construction solutions, instead of two materials, we get one solution, eg a roof that combines elements of a classic structure with photovoltaics. Which in turn results in savings on:

- assembly, one team installs tiles and photovoltaic tiles

- material cost, instead of roof tiles we have solar tiles, facade panels are installed instead of the facade

- high energy productivity which is characterized by the CIGS technology

CIGS BIPV construction technology of the future

Durability, effective work and aesthetics make CIGS conquer the construction and construction market. Thanks to companies such as Eterbright, which integrate construction solutions such as roof tiles with photovoltaics to create solar roof tiles, the development of technology is focused on BIPV.

Thin-film photovoltaic technologies make practical use of photovoltaics in urban space and landscape architecture, creating ecological integrated BIPV solutions. The construction niche in photovoltaics is gradually being filled by photovoltaic tiles and facade panels. This creates an interesting trend and causes that CIGS, despite the relative share in the PV market, begins to play an increasingly important role in the specificity of integrated photovoltaics.

Most Popular

Kapaciteti Srbije za Fotonaponsku (PV) Energiju

Serbia Capabilities for Photovoltaic (PV) Energy

Subscribe To Our Weekly Newsletter

Categories

- HJTPV.com

- HJT Technology

- HJT Producers

- HJT Solar Panels

- HJT Solar Panel Mysolar Gold 740W

- HJT Solar Panel Mysolar Gold 640W

- HJT Solar Panel AEsolar COMET 720W

- HJT Solar Panel AESOLAR COMET 650W

- HJT Solar Panel Bi Chaser Akcome 120 Cells

- HJT Solar Panel HuaSun HS-B120DS

- HJT Solar Panel Jinergy JNHM120 Cells

- HJT Solar Panel Risen Hyper-ion

- HJT Solar Panel QW Solar Giwa5 730W

- HJT Solar Panel QW Solar Giwa5 640W

- HJT Solar Panel Risen RSM120

- Cleaning Robot

- HJT Solar CELLS

- News&Knowledge

- Contact

- HJTPV.com

- HJT Technology

- HJT Producers

- HJT Solar Panels

- HJT Solar Panel Mysolar Gold 740W

- HJT Solar Panel Mysolar Gold 640W

- HJT Solar Panel AEsolar COMET 720W

- HJT Solar Panel AESOLAR COMET 650W

- HJT Solar Panel Bi Chaser Akcome 120 Cells

- HJT Solar Panel HuaSun HS-B120DS

- HJT Solar Panel Jinergy JNHM120 Cells

- HJT Solar Panel Risen Hyper-ion

- HJT Solar Panel QW Solar Giwa5 730W

- HJT Solar Panel QW Solar Giwa5 640W

- HJT Solar Panel Risen RSM120

- Cleaning Robot

- HJT Solar CELLS

- News&Knowledge

- Contact

Related Posts

Maximizing Agrivoltaic Performance with HJT/TOPCon Modules

MySolar a solar panel manufacturer, announced in 2023 that it has launched commercially available HJT + perovskite solar cells with a power output of 250 W. The company was founded in 2013 and has since become one of the leading solar panel manufacturers in Poland. HJT + perovskite cells are a new technology with the potential to revolutionize the solar industry.

Innovative 5MW Solar Farm in Northern Italy: Energy Excellence Meets Sustainable Agriculture

MySolar a solar panel manufacturer, announced in 2023 that it has launched commercially available HJT + perovskite solar cells with a power output of 250 W. The company was founded in 2013 and has since become one of the leading solar panel manufacturers in Poland. HJT + perovskite cells are a new technology with the potential to revolutionize the solar industry.

Kapaciteti Srbije za Fotonaponsku (PV) Energiju

Kapaciteti Srbije za PV Instalacije 1. Obilje pogodnog zemljišta: Srbija ima velike površine zemljišta pogodnog za fotonaponske (PV) instalacije. Topografija zemlje uključuje ravne ravnice, posebno

Serbia Capabilities for Photovoltaic (PV) Energy

Serbian Land Capabilities for PV Installations 1. Abundance of Suitable Land:Serbia has vast expanses of land suitable for photovoltaic (PV) installations. The country’s topography includes