- HJTPV.com

- HJT Technology

- HJT Producers

- HJT Solar Panels

- HJT Solar Panel Mysolar Gold 740W

- HJT Solar Panel Mysolar Gold 640W

- HJT Solar Panel AEsolar COMET 720W

- HJT Solar Panel AESOLAR COMET 650W

- HJT Solar Panel Bi Chaser Akcome 120 Cells

- HJT Solar Panel HuaSun HS-B120DS

- HJT Solar Panel Jinergy JNHM120 Cells

- HJT Solar Panel Risen Hyper-ion

- HJT Solar Panel QW Solar Giwa5 730W

- HJT Solar Panel QW Solar Giwa5 640W

- HJT Solar Panel Risen RSM120

- Cleaning Robot

- HJT Solar CELLS

- News&Knowledge

- Contact

- HJTPV.com

- HJT Technology

- HJT Producers

- HJT Solar Panels

- HJT Solar Panel Mysolar Gold 740W

- HJT Solar Panel Mysolar Gold 640W

- HJT Solar Panel AEsolar COMET 720W

- HJT Solar Panel AESOLAR COMET 650W

- HJT Solar Panel Bi Chaser Akcome 120 Cells

- HJT Solar Panel HuaSun HS-B120DS

- HJT Solar Panel Jinergy JNHM120 Cells

- HJT Solar Panel Risen Hyper-ion

- HJT Solar Panel QW Solar Giwa5 730W

- HJT Solar Panel QW Solar Giwa5 640W

- HJT Solar Panel Risen RSM120

- Cleaning Robot

- HJT Solar CELLS

- News&Knowledge

- Contact

Part of HJT Technology

0BB technology

On this Site You Will Read About

Explore the Experts

BusBar what is it?

Busbar (BB) technology in photovoltaic (PV) cells refers to the conductive metal strips or wires that are printed or placed on the surface of solar cells. The primary function of busbars is to collect and transfer the electrical current generated by the solar cell to the external circuitry or other cells within a module. The design and configuration of busbars have a significant impact on the efficiency, cost, and overall performance of the solar module.

Bus bars are commonly used in electrical panels, switchboards, and other power distribution systems to connect electrical loads to the main power source. They are also used to distribute power to multiple circuits or devices, providing a central point of connection for the electrical system.

Bus bars can come in various shapes and sizes, depending on the specific application and the amount of electrical current they need to handle. They can be flat or cylindrical and can be made with different thicknesses and widths to handle different levels of current.

In the context of photovoltaic (PV) technology, bus bars are used to connect the solar cells within a module, and then connect the modules to form a solar panel. The use of bus bars in PV modules has evolved over time, from a single bus bar to multiple bus bars (such as in MBB technology) to improve the module efficiency and performance.

Key Aspects of Busbar Technology

Function of Busbars

- Current Collection and Transfer: When light hits the PV cell, it generates electrical current. Busbars are responsible for collecting this current from the thin grid lines or fingers on the cell surface and then transferring it to the module’s interconnections. This allows the current to flow from one cell to the next and eventually to the module’s external terminals.

- Reduction of Series Resistance: Busbars provide a low-resistance path for the current to travel across the cell, reducing series resistance losses and improving the efficiency of the cell.

Evolution of Busbar Technology

- Traditional 2-5 Busbar Designs: Older PV technologies used fewer busbars, usually between 2 and 5, which were thick metal strips running across the cell surface. While these designs are simpler and cheaper, they create shading on the cell surface and have higher resistive losses, limiting the cell’s efficiency.

- Multi-Busbar (MBB) Technology: More modern PV cells use multi-busbar designs, such as 9BB, 12BB, 15BB, 18BB, or even 22BB. The increase in the number of busbars reduces the width of each busbar, thereby minimizing shading on the cell surface and improving efficiency. The reduced width also helps in lowering resistive losses since the current does not have to travel far to reach a busbar.

- Smart Wire and Advanced Interconnection: Advanced techniques like smart wire interconnection (SWCT) use very fine wires instead of wide busbars to collect and transport current. This further reduces shading and resistive losses while maintaining strong electrical connections.

Benefits and Trade-offs of Busbar Technology

- Efficiency Improvements: Increasing the number of busbars reduces shading and resistive losses, thus improving overall cell efficiency. However, there is a limit to how much efficiency can be improved as more busbars add to the manufacturing cost and complexity.

- Lower Cell Temperatures: With more busbars, the current pathways are shorter, reducing the heating effect due to resistive losses. This helps keep the cell cooler, improving its performance and lifespan.

- Material Costs: More busbars mean more silver paste or other conductive materials are required. Since silver is an expensive material, higher busbar counts can increase costs. However, using thinner busbars helps to offset this increase.

Explore the Experts

Zero "0" BusBar what is it?

Zero Busbar (0BB) technology is an advanced design in solar photovoltaic (PV) cells where the traditional metal busbars are completely removed from the surface of the cell. In standard solar cells, busbars are metal strips printed on the cell surface to collect and transfer electrical current. However, in 0BB technology, alternative methods like conductive adhesives, smart wire technology (SWCT), or ultra-thin wires are used to replace the busbars.

Key Features of 0BB Technology

No Visible Busbars: Unlike traditional solar cells that have visible metal lines (busbars) across the surface, 0BB cells do not have these lines, which maximizes the active area for sunlight absorption.

Increased Efficiency: By eliminating shading caused by busbars, 0BB technology allows more sunlight to reach the active cell surface, improving the cell’s power output and overall efficiency.

Reduced Resistive Losses: The absence of busbars reduces the electrical resistance encountered when the current travels across the cell, leading to better performance and lower losses.

Cost Benefits: Traditional busbars require significant amounts of expensive silver paste. 0BB reduces or eliminates the need for this silver, potentially lowering material costs and production expenses.

In summary, Zero Busbar (0BB) technology is an approach in solar PV cells to enhance efficiency and reduce costs by eliminating traditional busbars and using alternative current collection methods that increase the active surface area for light absorption.

Explore the Experts

Smart Wire Technology(SWTC) what is it?

Smart Wire Technology (SWCT) is an advanced interconnection technology used in solar photovoltaic (PV) cells to replace traditional busbars with a network of ultra-thin wires. This technology aims to enhance the electrical performance of solar modules by improving current collection, reducing shading losses, and minimizing material costs.

How SWCT Works

- Thin Wires Instead of Busbars: SWCT uses a grid of extremely fine, round wires (often made of copper and coated with a conductive layer) to replace the traditional flat busbars that collect and transport electrical current within the cell. These wires are much thinner than conventional busbars, typically around 0.1 mm in diameter.

- More Contact Points: The smart wire grid provides multiple contact points across the cell’s surface, enhancing current collection and reducing resistance. This is particularly beneficial for high-efficiency cell types like HJT (Heterojunction).

- Embedded in a Conductive Adhesive Mesh: The wires are embedded in a conductive adhesive, which bonds the wires to the cell and improves electrical conductivity. This adhesive layer also provides mechanical flexibility, allowing for better stress distribution and reduced risk of cell damage.

Applications

SWCT is often used in high-efficiency solar cells, like HJT (Heterojunction) or PERC (Passivated Emitter Rear Cell), where optimizing efficiency and minimizing losses are key. It is especially popular in combination with zero busbar (0BB) designs, where traditional busbars are eliminated in favor of smart wire grids.

In summary, SWCT (Smart Wire Technology) is an interconnection method that improves solar cell efficiency and durability by using a grid of thin wires to replace traditional busbars, reducing shading, enhancing electrical performance, and reducing material costs.

Explore the Experts

0 BusBar Technology (ZBB) what is it?

This is a new design for solar cell power conducting design. Instead of stripes as in MBB or SMBB technology, ZBB has very tiny wires for transferring energy into cells and between cells. The simple way explanation for ZBB is the smallest interconnection at the solar cell that is better for the performance and strength of cell.

Smart Wire for no BusBar

The key element of SmartWire is the copper wire composite film, which mainly consists of an electrically insulating optically transparent film, an adhesive layer on the film surface, and multiple parallel coppers wires (tabbing ribbons) coated and embedded within the adhesive layer. The copper wires are bonded to the surface of the film using the adhesive layer, and their surface protruded with a low-melting-point alloy coating from the adhesive layer.

The alloying of the film and grid is achieved through lamination. The copper wire composite film is connected to the solar cell, serially connecting the solar cells. It is then overlapped with the encapsulation film, backsheet, or glass, and a stable electrical connection is formed between the tabbing ribbons and the grid during the heating lamination process.

The copper wire composite film is laminated on the surfaces of adjacent solar cells to form a series connection. Compared to conventional solar cell packaging processes, the interconnection of the main grid solar cells is achieved by using a new type of stringer machine to lay the copper wire composite film on the front and back surfaces of two cells, enabling the series connection of adjacent cells. After the cells are interconnected, they are arranged and stacked, and under certain lamination temperatures and pressure, the copper wires and the solar cell grids are pressed together to form an ohmic contact.

0 Busbar solar cells and panels offer the following important benefits:

- Increased efficiency

The surface where busbar ribbons are located isn’t used for generating electricity. Removing the ribbons creates more space on each cell and increases panel efficiency.

The current half-cell module cells need to be spaced apart, which also takes up valuable space on the panel.

- Reduced shading

Busbar ribbons can also shade PV cells. In multi-busbar modules, round wires instead of flat, rectangular ribbons already reduce a substantial amount of shading. But with zero busbar technology, the shading is cut to zero.

- Reduced cost of materials

Busbar ribbons are usually flat strips or round wires made of silver- or tin-plated copper, although other, less common compositions exist.

Silver plating enhances conductivity on the front and reduces oxidation on the rear side. Zero busbar panels don’t require those metals, which can reduce the overall cost.

- Aesthetics

For residential and even for C&I the aesthetic of a solar panel is probably an important deciding factor for you.

0BB PV panels offer a new generation of stylish, all-black aesthetics. They look modern and more sophisticated than earlier models with busbars.

- Microcracks and hotspots lower the risk

The manifestation of micro-cracks in solar panels can occur at various stages of their transport or installation and throughout their entire life cycle. Thermal cycling, which involves changes in temperature during the day and night, is one of the main causes of micro-cracks after installation.

As the materials in the panel expand due to heat during warmer hours and contract during colder hours, the discrepancy in the rates at which different materials expand can lead to thermo-mechanical cracks under the busbars. The copper in busbars, for example, shrinks faster than the silicon, making it more susceptible to micro cracks. While these micro cracks may not always affect the efficiency of the modules, they can result in power output losses of up to 2.5%.

- Better Performance in Shade

Shading causes a significant problem for PV module efficiency. When an area on a solar panel is partly in shade, it affects the electrical conduction. So, not only is the shaded area unable to produce energy, but the conductivity of busbars is also reduced.

Busbar-less panels have reduced the distances current needs to travel, significantly improving efficiency in the shade.

Explore the Experts

Advantages and Disadvatnages of 0BB

In the context of solar PV technology, particularly heterojunction (HJT) cells, “0BB” or “Zero Busbar” technology refers to an advanced design approach aimed at improving the efficiency and aesthetics of solar cells. Here’s a detailed overview:

Advantages of Zero Busbar (0BB) Technology

- Higher Efficiency: By eliminating the traditional silver busbars on the cell surface, more of the active cell area is exposed to sunlight. This leads to better photon absorption and overall increased power output.

- Reduced Electrical Losses: Traditional busbars introduce resistive losses; with 0BB, these losses are minimized, improving the cell’s performance, particularly in HJT cells that benefit from low-temperature coefficients.

- Aesthetic Design: 0BB cells have a cleaner, more uniform appearance as there are no visible silver lines on the surface. This aesthetic enhancement is particularly valued in applications where appearance is important, such as in building-integrated photovoltaics (BIPV).

- Cost-Effective Material Usage: The traditional silver busbars require a significant amount of costly silver paste. 0BB technology reduces or eliminates the use of this silver, lowering material costs and potentially reducing the overall cost of manufacturing.

- Enhanced Durability: With fewer metal components on the surface of the cells, 0BB technology can improve mechanical robustness and reduce the potential for microcracks that can degrade performance over time.

Disadvantages of Zero Busbar (0BB) Technology

- Manufacturing Complexity: Transitioning to 0BB design requires advanced manufacturing processes and technologies, such as conductive adhesives or smart wire interconnection (SWCT), which can increase initial setup costs.

- Reliability Concerns: The absence of traditional busbars means that the interconnection methods must be highly reliable. New methods, like wire bonding or conductive glue, must withstand thermal cycling and mechanical stress over the lifespan of the module.

- Limited Adoption: While 0BB technology offers significant benefits, it is still not widely adopted, which can mean less availability of components and a lack of standardization across the industry.

Why solar panels with N-Type?

Best Performance

Highest Efficiency and power of solar panels

Long Warranty

30 years with only 0,25% annual degradation

inspiring technology

N-type HJT Bifacial Cells cover in Glass glass frame

What N-Type Technology offer

N-Type Advantage

Zero LeTID&PID

Zero LID

Lowest Temperature Coefficient

Highest Average Efficiency >24%

state-of-the-art Solar Solution

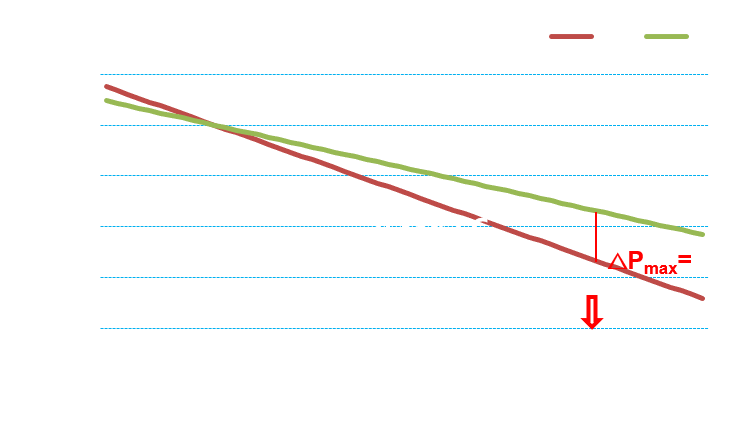

0BB comparison

Comparison to Other Technologies

- Traditional Busbar Cells: Standard solar cells use 3-5 busbars to collect and transfer electricity, which creates shading and reduces efficiency. In contrast, 0BB technology eliminates these losses and improves power output.

- Multi-Busbar (MBB) Designs: MBB is an intermediate technology that uses multiple thin busbars to reduce shading and improve efficiency. However, 0BB goes a step further by eliminating busbars altogether, potentially offering even higher efficiency.

- Shingled and Half-Cut Cells: These technologies also aim to improve efficiency and reduce losses. Shingled cells overlap cell strips to minimize resistive losses, while half-cut cells split standard cells to reduce the impact of shading. Both can be complementary to 0BB technology, and in some cases, a combination of these techniques with 0BB can be used to optimize performance.

In summary, 0BB technology in solar PV, especially in HJT cells, represents a cutting-edge approach to increasing efficiency, reducing material costs, and improving aesthetics. While there are challenges in terms of manufacturing complexity and reliability, the potential benefits in terms of power output and cost-effectiveness make it a promising development in the PV industry.

Overall Comparison to Traditional Technologies

- PID and LID: Traditional cells with busbars are more susceptible to PID and LID, which affect the long-term performance of the module. 0BB in HJT cells significantly mitigates these degradation effects, leading to a more reliable and durable performance over time.

- Efficiency: 0BB increases efficiency by exposing more cell surface area to sunlight and minimizing resistive losses, surpassing both traditional busbar cells and even multi-busbar (MBB) designs in performance.

- Cost and Silver Paste Savings: The reduced usage of silver paste in 0BB provides a cost advantage over traditional busbar designs. This is especially relevant given the volatility and expense of silver as a raw material.

- Temperature Performance: The combination of HJT’s low temperature coefficient and 0BB’s minimized resistive losses result in a solar module that maintains efficiency across a wide range of temperatures, performing well in both cold and hot climates.

In summary, 0BB technology in HJT solar cells offers superior resistance to PID and LID, enhances efficiency by reducing shading and resistive losses, significantly lowers costs through reduced silver paste usage, and maintains better performance across varying temperatures due to an improved temperature coefficient.

Why choose HJT Panels?

N-Type Technology Profits

Why HJT Panels Are The Best?

Best Advantage of N-Type Solar Panels

Explore the Experts

Best N-Type Producers

commit to HJT Solar Revolution

N-type Solar Panel- best Solution for Utility scale investitions?

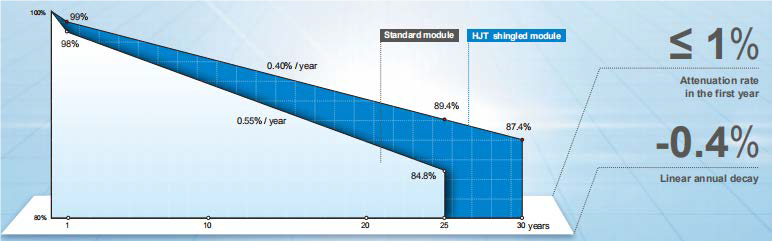

Long warranty for power production >30 Years

Highest Efficiency >24%

Low Yearly degradation, only >0,25%

Best Bifiaciality efficiency >95%

Lowest Temperature Coefficient 0,24%-026%/°C

Very low modules failure risk factor

All You Need To Know About N-type Technology

frequently asked questions

HJT solar panels have the best efficiency in serial production. Scope of it is between 21%-22,53% with R&D plan even to 26%. N-type module has the best performance and most reliable characteristic resistance for most common fail from all over solar technology.

HJT with N-type technology solar Panels with 120 cells have a scope of power between 370W-390W and for 144 cells 425W – 470W. Newest standard 132 cells has standard 700W from Mysolar manufacturer. At the end of 2022 Power of HJT modules will achieve >500W, >600W and now >700W.

N-type technology ensures a long safe warranty for 30 years of production and 12 -30 years for a panel, depends on the producers. It’s more approx. 5 years than common PERC panels.

HJT solar panels with N-type cells are value for money solutions. Compare with standard backsheet modules, the price for Heterojunction is a little bit more. But compared with Bifacial, glass-glass solar panels, HJT is the best solution and has more advantages worth a few % higher price.

Higher power, bifaciality, efficient production under extreme conditions, combined with the world’s lowest degradation, no LID and PID effects and a double glass structure (GLASS-GLASS), allows you to generate significant savings over 30 years of use compared to PERC panels.

Glass is the best protection for the silicon cells that are the heart of the photovoltaic module. A cell is a unit that generates electricity, but it is made of a delicate material that needs to be reinforced and secured externally. For this purpose, we have a good ally in the form of solar glass, which, in addition to being transparent, is an electrical insulator.

HJT PV team is not only a trusted advisor but solar panels broker. We are helping Clients from all over the world connect to trusted and checked HJT producers. Direct cooperation ensures the best prices and fast delivery, to all destinations.

N-type Solar Panels Sales and distribution

EPC Cooperation

general contractor of photovoltaic investments

Distributor In Europe

Container and Mega Watt sales

Photovoltaic Broker

mediation in the purchase directly from the manufacturer