- HJTPV.com

- HJT Technology

- HJT Producers

- HJT Solar Panels

- HJT Solar Panel Mysolar Gold 740W

- HJT Solar Panel Mysolar Gold 640W

- HJT Solar Panel AEsolar COMET 720W

- HJT Solar Panel AESOLAR COMET 650W

- HJT Solar Panel Bi Chaser Akcome 120 Cells

- HJT Solar Panel HuaSun HS-B120DS

- HJT Solar Panel Jinergy JNHM120 Cells

- HJT Solar Panel Risen Hyper-ion

- HJT Solar Panel QW Solar Giwa5 730W

- HJT Solar Panel QW Solar Giwa5 640W

- HJT Solar Panel Risen RSM120

- Cleaning Robot

- HJT Solar CELLS

- News&Knowledge

- Contact

- HJTPV.com

- HJT Technology

- HJT Producers

- HJT Solar Panels

- HJT Solar Panel Mysolar Gold 740W

- HJT Solar Panel Mysolar Gold 640W

- HJT Solar Panel AEsolar COMET 720W

- HJT Solar Panel AESOLAR COMET 650W

- HJT Solar Panel Bi Chaser Akcome 120 Cells

- HJT Solar Panel HuaSun HS-B120DS

- HJT Solar Panel Jinergy JNHM120 Cells

- HJT Solar Panel Risen Hyper-ion

- HJT Solar Panel QW Solar Giwa5 730W

- HJT Solar Panel QW Solar Giwa5 640W

- HJT Solar Panel Risen RSM120

- Cleaning Robot

- HJT Solar CELLS

- News&Knowledge

- Contact

Part of HJT Technology

Temperature coefficient in PV

On this Site You Will Read About

Explore the Experts

HJT Temperature Coefficient

Temperature Coefficient what is it?

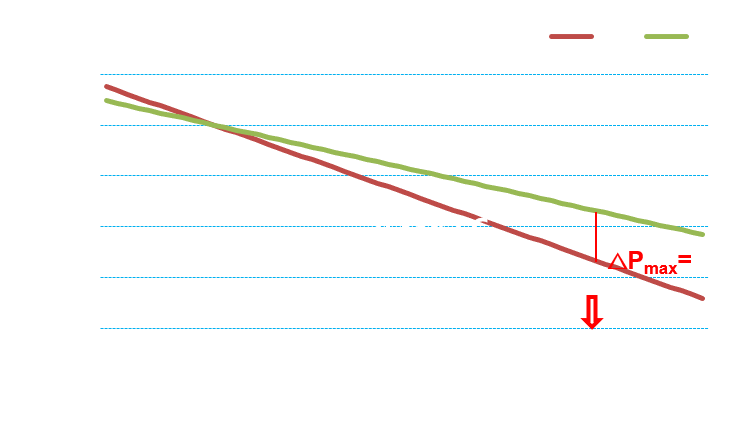

The temperature coefficient in PV refers to the change in the output power of a photovoltaic (PV) module or cell as the temperature changes. It is usually expressed as a percentage change in power output per degree Celsius. For example, a PV module with a temperature coefficient of -0.5%/°C will have a 0.5% decrease in power output for every 1°C increase in temperature. The temperature coefficient can vary depending on the type of PV technology used and the materials used in the module or cell.

Why HJT technology has the best temperature coefficient?

Heterojunction (HJT) technology is a type of PV technology that uses different semiconductor materials in the same solar cell to improve performance and efficiency. HJT cells typically consist of a thin layer of amorphous silicon (a-Si) or microcrystalline silicon (µc-Si) on top of a crystalline silicon (c-Si) substrate.

HJT cells have a lower temperature coefficient than traditional c-Si cells because the thin layer of a-Si or µc-Si on top of the c-Si substrate acts as a buffer, reducing the impact of temperature changes on the output power of the cell.

Heterojunction technology has been found to have a temperature coefficient of -0.2% to -0.3% per degree Celsius (Mysolar 700W modules have 0,26%), which is significantly lower than the -0.4% to -0.5% per degree Celsius typically seen in traditional c-Si cells.

This makes HJT technology a more attractive option for PV systems that will be exposed to high temperatures, as they will experience less performance degradation due to temperature changes.

Why Temperature Coefficient affect on performance?

Best Performance

Lower Tem. Coefficient = Highest Efficiency and power of solar panels. Less power loss in standard operating temperature.

Long Warranty

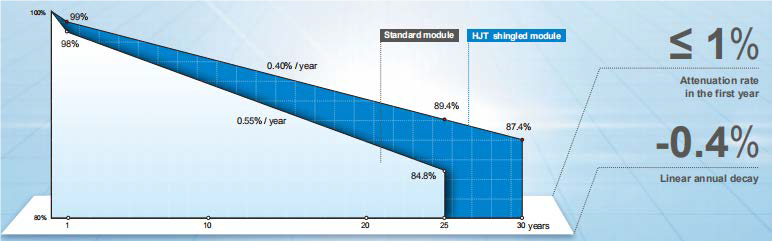

The lowest Temperature Coefficient gives a lower chance of issues and helps increase the warranty period of 30 years with only 0,25% annual degradation

Important for Utility Project

In Big scale utility investments like solar farms each aspect of improving performance and cutting cost counting in Mega Watts is crucial for ROI.

Explore the Experts

Temperature Coefficient, How to Calculate?

How to calculate the temperature coefficient?

Temperature Coefficient (α) = (ΔP/P) / (ΔT) α = [(98-100)/100] / (50-25) = -0.02 / 25 = -0.0008 or -0.08%/°C

It’s important to note that this is just an example and the temperature coefficient can vary depending on the solar panel and its technology.

Also, it’s important to measure power output under standard test conditions (STC) which are: Irradiance of 1000W/m², Air mass of 1.5, and Cell temperature of 25°C.

It’s also worth noting that the temperature coefficient of a solar panel can change over time, due to factors such as aging or environmental conditions, so it’s important to regularly measure and track the temperature coefficient of a solar panel to ensure that it is operating within its optimal temperature range.

What is the pattern for the count temperature coefficient?

The pattern for determining the temperature coefficient of a solar panel is to measure the change in power output of the panel as the temperature changes. The process typically involves the following steps:

- Measure the power output of the solar panel at a reference temperature, such as 25°C. This will be the initial power output (P).

- Change the temperature of the solar panel to a different value, such as 50°C.

- Measure the power output of the solar panel at the new temperature. This will be the final power output (Pf).

- Calculate the change in power output (ΔP) by subtracting the initial power output (P) from the final power output (Pf).

- Calculate the change in temperature (ΔT) by subtracting the reference temperature (25°C) from the final temperature (50°C).

- Use the formula for temperature coefficient to calculate the temperature coefficient (α): Temperature Coefficient (α) = (ΔP/P) / (ΔT)

- Repeat steps 2-6 for different temperatures to get a more accurate picture of how the temperature coefficient changes with temperature.

It’s important to note that this pattern is a general one, it is always recommended to follow the manufacturer’s instructions to get the accurate temperature coefficient, as well as taking into consideration the measurement standards that were used.

Why temperature coefficient is important in hot climate installation?

The temperature coefficient is important in hot climate installations because it affects the performance and efficiency of a solar panel. As temperature increases, the output power of a solar panel decreases, which can result in a significant reduction in the overall performance of a solar PV system.

In hot climates, solar panels are exposed to high temperatures for long periods of time, which can cause the temperature coefficient to have a greater impact on the performance of the system. This is because the temperature coefficient becomes more negative as the temperature increases, which means that the power output of the solar panel decreases at a faster rate as the temperature rises.

For example, a solar panel with a temperature coefficient of -0.5%/°C at 25°C may have a temperature coefficient of -0.8%/°C at 50°C. This means that the power output of the solar panel decreases by 0.8% for every 1°C increase in temperature, which can result in a significant reduction in the overall performance of the system.

In addition to this, in hot climates, it’s also important to take steps to keep solar panels cool, such as shading or using a cooling system, to ensure that the solar panel is operating within its optimal temperature range, which improves the overall performance of the system.

Therefore, understanding the temperature coefficient of a solar panel is critical when installing PV systems in hot climates to ensure that the system is designed and optimized to perform well even under high-temperature conditions.

What N-Type HJT Technology offer

N-Type HJT Advantage

Zero LeTID&PID

Zero LID

Lowest Temperature Coefficient

Highest Average Efficiency >24%

state-of-the-art Solar Solution

How is construct N-type CELL?

Why temperature coefficient is important?

The temperature coefficient is important because it affects the performance and efficiency of a PV system. As temperature increases, the output power of a PV module decreases, which can result in a significant reduction in the overall performance of a PV system. This can be especially significant in hot climates where PV systems are exposed to high temperatures for long periods of time. Additionally, temperature coefficient is also important in the design and optimization of PV systems. By understanding the temperature coefficient of a PV module, engineers can design a PV system that will perform well even in high temperature environments. They can also use this information to estimate the energy output of a PV system under different temperature conditions. In summary, temperature coefficient is important in PV systems because it affects the performance and efficiency of the system, it's a key parameter in the design and optimization of PV systems, and it's useful in estimating the energy output of a PV system under different temperature conditions.

what pv technology has best temperature coefficient?

Different types of PV technologies have different temperature coefficients. Generally, the temperature coefficient of a PV module is determined by the type of semiconductor material used in the module. Among the most common PV technologies, crystalline silicon (c-Si) solar cells have one of the highest temperature coefficients, typically in the range of -0.4% to -0.5% per degree Celsius. On the other hand, thin-film PV technologies, such as cadmium telluride (CdTe) and copper indium gallium selenide (CIGS), have lower temperature coefficients, typically in the range of -0.2% to -0.3% per degree Celsius. The latest technology of perovskite solar cells have an even lower temperature coefficient, usually around -0.1%/°C. It is worth mentioning that temperature coefficient is not the only parameter that determine the performance and efficiency of a PV system, and other factors like conversion efficiency and shading also play important role in the overall performance of the system.

Why choose HJT Panels?

N-Type Technology Profits

Why HJT Panels Are The Best?

Best Advantage of N-Type Solar Panels

Explore the Experts

Best N-Type Producers

Risen

Jolywood

commit to HJT Solar Revolution

N-type Solar Panel- best Solution for Utility scale investitions?

Long warranty for power production >30 Years

Highest Efficiency >22,8%

Low Yearly degradation, only >0,25%

Best Bifiaciality efficiency >95%

Lowest Temperature Coefficient 0,24%-026%/°C

Very low modules failure risk factor

All You Need To Know About HJT N-type Technology

frequently asked questions

HJT solar panels have the best efficiency in serial production. Scope of it is between 21%-22,53% with R&D plan even to 26%. N-type module has the best performance and most reliable characteristic resistance for most common fail from all over solar technology.

HJT with N-type technology solar Panels with 120 cells have a scope of power between 370W-390W and for 144 cells 425W – 470W. Newest standard 132 cells has standard 700W from Mysolar manufacturer. At the end of 2022 Power of HJT modules will achieve >500W, >600W and now >700W.

N-type technology ensures a long safe warranty for 30 years of production and 12 -30 years for a panel, depends on the producers. It’s more approx. 5 years than common PERC panels.

HJT solar panels with N-type cells are value for money solutions. Compare with standard backsheet modules, the price for Heterojunction is a little bit more. But compared with Bifacial, glass-glass solar panels, HJT is the best solution and has more advantages worth a few % higher price.

Higher power, bifaciality, efficient production under extreme conditions, combined with the world’s lowest degradation, no LID and PID effects and a double glass structure (GLASS-GLASS), allows you to generate significant savings over 30 years of use compared to PERC panels.

Glass is the best protection for the silicon cells that are the heart of the photovoltaic module. A cell is a unit that generates electricity, but it is made of a delicate material that needs to be reinforced and secured externally. For this purpose, we have a good ally in the form of solar glass, which, in addition to being transparent, is an electrical insulator.

HJT PV team is not only a trusted advisor but solar panels broker. We are helping Clients from all over the world connect to trusted and checked HJT producers. Direct cooperation ensures the best prices and fast delivery, to all destinations.

N-type Solar Panels Sales and distribution

EPC Cooperation

general contractor of photovoltaic investments

Distributor In Europe

Container and Mega Watt sales

Photovoltaic Broker

mediation in the purchase directly from the manufacturer