How to start building a solar farm?

Planning and implementation of a solar farm is a complex process, divided into many stages. The most important elements are:

- tender for execution

- equipment that will be used photovoltaic modules, structures, inverters or transformer stations

- design of a photovoltaic installation

- PV farm service

Tender for a solar farm

Investing in photovoltaics is becoming more and more popular, and it is difficult to find reliable information in the maze of contradictory information. We always start work on a PV farm with a location. In this case, the key factors for the location of the solar farm are:

– soil class on which the investment is planned

– the plot is as flat as possible

– the PV installation can be built towards the south or east-west

– there is no more than 200 meters to the medium voltage line (in the case of an on-grid system)

– has access to a road that will allow the transport of construction equipment

– the safest assumption is the size of a photovoltaic plot of at least 2ha (1mW)

The best assembly teams help to comprehensively analyze all possibilities at the stage of selection and design. The best choice is a company specializing in the comprehensive implementation of the entire investment. After getting through the maze of regulations and permits related to investing in a solar farm, you should choose key components such as:

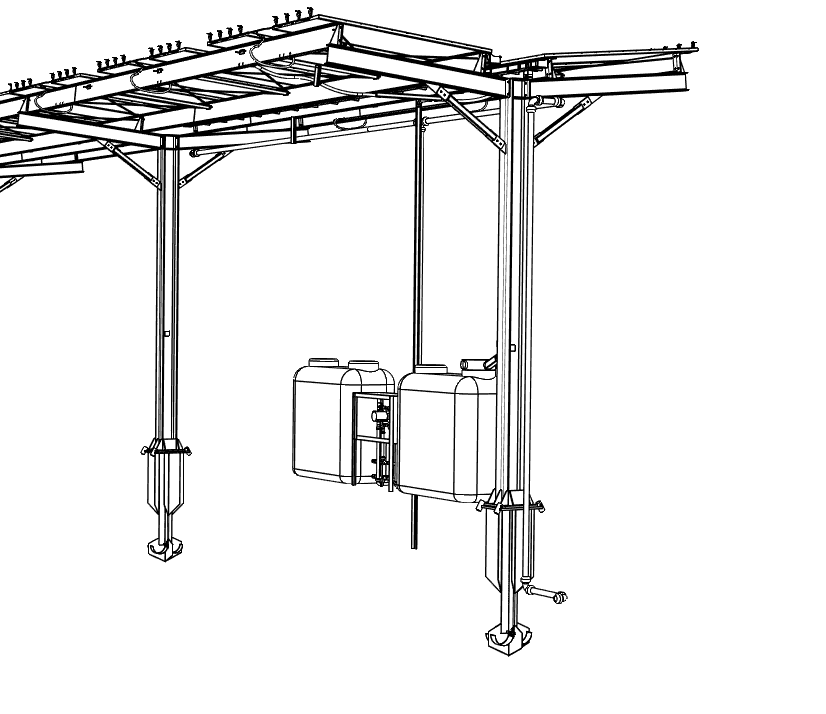

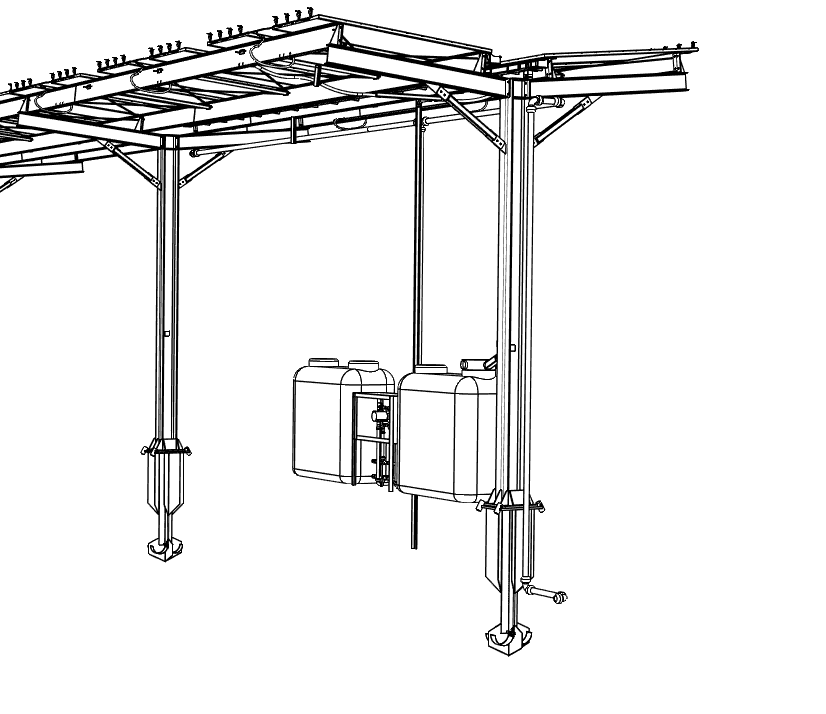

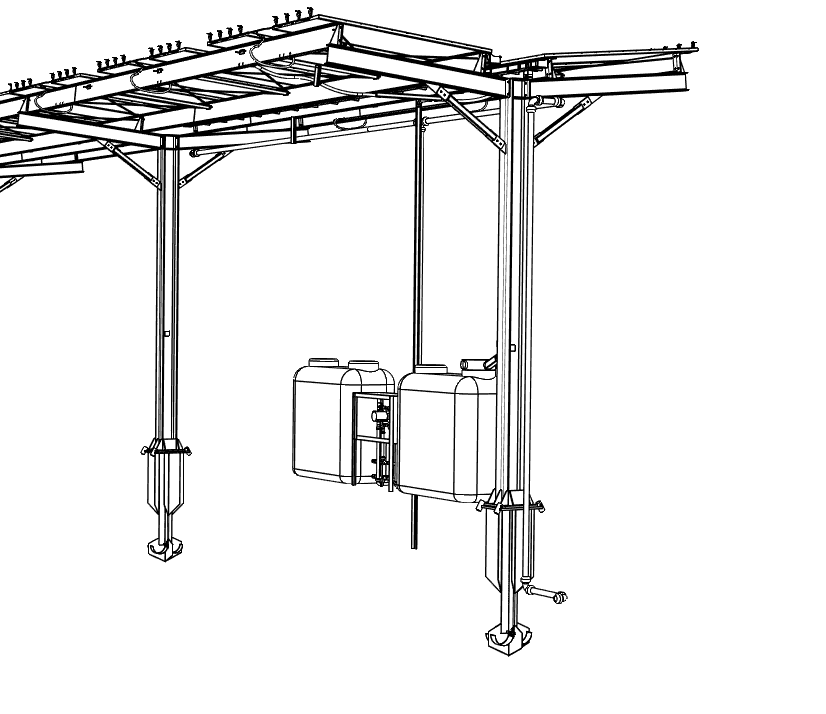

- Photovoltaic assembly structures such as AKCOME Metals

- Photovoltaic inverters dedicated to Kehua’s business solutions

- HJT AKCOME, Jinergy or Risen solar modules that produce energy on both sides

Photovoltaic modules for a photovoltaic power plant

The photovoltaic structure is the backbone of the entire system, while the photovoltaic modules cover it. The world is dominated by two main development lines in the production technology of N-Type (HJT) solar panels with the undisputed leaders ACKOME, Jinergy and Risen. The second is PERC, i.e. P-Type, which is divided between several manufacturers, against which ZnShine stands out with its Graphene cover, a 12-year manufacturer’s warranty and a 30-year warranty on power yield. The most important elements of photovoltaic panels dedicated to farms and large solar installations are:

– N-Type technology, which is the fastest-growing photovoltaic technology on the market, e.g. n-TOPCON Jolywood and HJT AKCOME.

– P-type technology gives the largest selection of manufacturers, which is also associated with difficulties in the selection and worse parameters.

– two-sidedness, i.e. Bifacial Photovoltaic Modules producing energy up to 30% more.

– Double Glass or Glass-Glass modules with glass on both sides of the module. This reduces the risk of degradation due to weather conditions and fire.

– Manufacturer’s warranty for modules. Jolywood has the highest warranty for n-type for 15 years and for PERC ZnShine for 12 years. 12 years have as well all HJT producers like Jinergy, Risen and AKCOME.

– Warranty for linear power loss where you should choose a 30-year warranty with a minimum of 83% after this period ZnShine or Jolywood, Risen, AKCOME and Jinergy as much as >87%

– The degradation in the first year, which always occurs most at the beginning of the operation of N-Type photovoltaic modules, is characterized by 1%, while PERC enriched with Gall instead of Boron 2.5-3%.

– The annual degradation, after the first year in the case of Jolywood and HJT solar panels 0.4% and ZnShine 0.5%, is one of the best performances on the market in bifacial and glass-glass modules.

– It is important to secure the manufacturer’s warranty, which is usually guaranteed by Munich RE and this means the highest level of protection in the world.

– Ranking of the ability and financial strength of the company producing TIER I Bloomberg modules. The modules included in the ranking are usually technology and sales leaders.

– The number of silicon cells usually determines the size of the modules and the standard is 120. More importantly, when choosing, it is worth taking into account the Half Cut modules, i.e. a module divided into two parts, each with 60 cells. As a result, shading and dirt have less impact on the entire module.

– 9BB or Multi BusBar, which is the optimal technology of energy dissipation from silicon cells.

– The production technology of silicon cells due to the crystals, indicates that the best choice of monocrystalline N-type Jolywood modules, Heterojunction N-type like Akcome and ZnShine PERC modules

– Temperature Coefficient of below <0.3%, one of the best in the world, achieved only HJT solar panels.

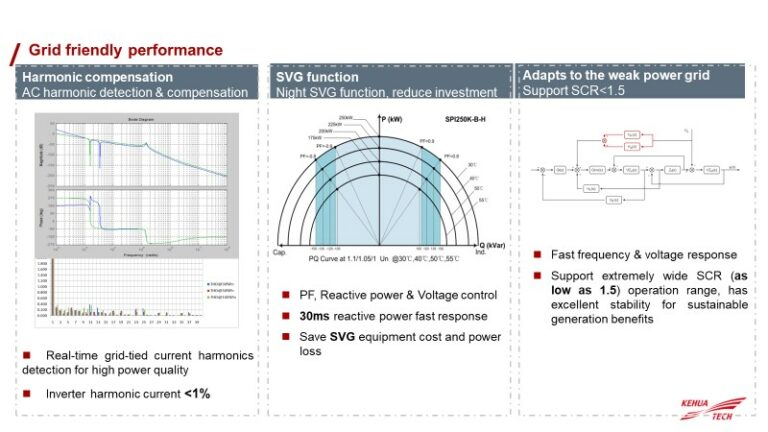

Photovoltaic inverters and the solar farm

If the structure is a skeleton and the modules are skin and eyes, then the Inverter is the heart and brain of a photovoltaic installation. In the case of photovoltaic farms, where the equipment usually works outdoors in extreme conditions, attention should be paid to the performance and experience of the manufacturer. The industrial nature of workmanship and the work characteristics distinguish KEHUA, which is one of the largest industrial suppliers of inverters. It has a string and central inverters. The differences between these two types of inverters are as follows:

String inverters are characterized by work on strings (strings) of photovoltaic modules. This means that the heart of the installation optimizes the individually connected PV modules into larger bundles. It is related to the optimization of MPPT (Maximum Power Point Tracking) operation, i.e. the selection of the optimal operation of individual modules as well as entire chains consisting of several to several dozen photovoltaic panels. In the case of solar farms, from the cost point of view, Kehua 250kW inverters are the best solution. There are 4 inverters per one megawatt of production, which control the operation of about 3,000 modules dedicated to solar farms( bifacial, N-type HJT modules). What to look for when choosing a string inverter:

– Outdoor working conditions require at least IP 65 resistance.

– Tight aluminum or metal housing will improve the durability of the inverters.

– Performance drop at high temperature, where 50 ° C is the limit for performance loss. At 50 C, few inverters operate at 98.6% of their efficiency, including KEHUA.

– Maximum voltage load from modules, which should not be less than 1000V.

– Number of MPPT Trackers and chains that can be optimized on one tracker.

– Maximum current expressed in Amps, connected to one MPPT tracker, where the Kehua inverter with 30 Amps stands out.

– The span of work at extreme loads, i.e. minimum and maximum loads, which values determine the start of work and the maximum load. And the greater the scope of work, the better the fit to the installation.

– The best proprietary monitoring system programmed by the inverter manufacturer and manages the installation.

– Possibility of data transmission in PLC technology using RS 485 transmission.

– Does the inverter work optimally with Bifacial PV modules such as Jolywood, Risen, AKCOME and Jinergy.

Kehua Industrial Inverter- when is reasonable?

Kehua Central Inverters are large-size and large-scale devices that can independently control the operation of large installations. As the name suggests, one device controls the entire photovoltaic installation. This has its advantages and disadvantages, as one inverter can solve the problem of configuration and optimization of a solar farm. On the other hand, there is a large specialized device that can work in certain conditions, i.e. flat terrain, similar module operation characteristics, no shading or dirt on solar panels. It does not work on groups of modules but on the entire installation, so the optimization detail is smaller. A solution with a central inverter is usually suitable for projects of several or even several dozen megawatts.

Construction of a solar farm.

Knowing what to do and with what components, it remains to choose the contractor of the solar farm. The key, in this case, is the experience not only in the assembly of investments in a solar farm but also in knowledge in the energy and technology industries. Therefore, in such a complex project, it is good to check the contractor in this respect. The ideal scenario for a solar power plant contractor is the one in which the assembly team is the distributor of the equipment they offer in the installation. This ensures that the proposed components are tested, the assembly will run smoothly, and the warranty and service will remain in one place. Such a choice can be HJTPV, which are distributors of N-type HJT modules, Gallium Dopped panels and specialized Kehua inverters. Another advantage is the specialization in business projects and photovoltaic installations for farmers and food producers. It is equally important that the assembly team is not from the other side of the country, as logistics and work in remote locations always pose additional problems.

The most important elements of a solar farm.

To sum up, when investing in photovoltaics, choose a flat area close to the pylons of the medium voltage grid. Choose a construction(AKCOME) for Jinergy or Risen bifacial photovoltaic modules and made of steel with a Magnelis coating. Modules to be selected should be made in N-Type/HJT or PERC technology with a graphene coating. Additionally, photovoltaic panels must produce energy from both sides (Bifacial) and be made of photovoltaic glass on both sides. In small and medium-sized photovoltaic farms, Kehua industrial inverters, distributed directly by HJTPV, will work best. The assembly team, on the other hand, should specialize in business projects and have experience in the energy industry.

Order and Purchase complex solutions for solar farms

Jacek Serwin

mail: j.serwin@eprad.pl

tel.: +48 793416519

Most Popular

Kapaciteti Srbije za Fotonaponsku (PV) Energiju

Serbia Capabilities for Photovoltaic (PV) Energy

Subscribe To Our Weekly Newsletter

Categories

- HJTPV.com

- HJT Technology

- HJT Producers

- HJT Solar Panels

- HJT Solar Panel Mysolar Gold 740W

- HJT Solar Panel Mysolar Gold 640W

- HJT Solar Panel AEsolar COMET 720W

- HJT Solar Panel AESOLAR COMET 650W

- HJT Solar Panel Bi Chaser Akcome 120 Cells

- HJT Solar Panel HuaSun HS-B120DS

- HJT Solar Panel Jinergy JNHM120 Cells

- HJT Solar Panel Risen Hyper-ion

- HJT Solar Panel QW Solar Giwa5 730W

- HJT Solar Panel QW Solar Giwa5 640W

- HJT Solar Panel Risen RSM120

- Cleaning Robot

- HJT Solar CELLS

- News&Knowledge

- Contact

- HJTPV.com

- HJT Technology

- HJT Producers

- HJT Solar Panels

- HJT Solar Panel Mysolar Gold 740W

- HJT Solar Panel Mysolar Gold 640W

- HJT Solar Panel AEsolar COMET 720W

- HJT Solar Panel AESOLAR COMET 650W

- HJT Solar Panel Bi Chaser Akcome 120 Cells

- HJT Solar Panel HuaSun HS-B120DS

- HJT Solar Panel Jinergy JNHM120 Cells

- HJT Solar Panel Risen Hyper-ion

- HJT Solar Panel QW Solar Giwa5 730W

- HJT Solar Panel QW Solar Giwa5 640W

- HJT Solar Panel Risen RSM120

- Cleaning Robot

- HJT Solar CELLS

- News&Knowledge

- Contact

Related Posts

Maximizing Agrivoltaic Performance with HJT/TOPCon Modules

MySolar a solar panel manufacturer, announced in 2023 that it has launched commercially available HJT + perovskite solar cells with a power output of 250 W. The company was founded in 2013 and has since become one of the leading solar panel manufacturers in Poland. HJT + perovskite cells are a new technology with the potential to revolutionize the solar industry.

Innovative 5MW Solar Farm in Northern Italy: Energy Excellence Meets Sustainable Agriculture

MySolar a solar panel manufacturer, announced in 2023 that it has launched commercially available HJT + perovskite solar cells with a power output of 250 W. The company was founded in 2013 and has since become one of the leading solar panel manufacturers in Poland. HJT + perovskite cells are a new technology with the potential to revolutionize the solar industry.

Kapaciteti Srbije za Fotonaponsku (PV) Energiju

Kapaciteti Srbije za PV Instalacije 1. Obilje pogodnog zemljišta: Srbija ima velike površine zemljišta pogodnog za fotonaponske (PV) instalacije. Topografija zemlje uključuje ravne ravnice, posebno

Serbia Capabilities for Photovoltaic (PV) Energy

Serbian Land Capabilities for PV Installations 1. Abundance of Suitable Land:Serbia has vast expanses of land suitable for photovoltaic (PV) installations. The country’s topography includes