What is Multi BusBar Technology?

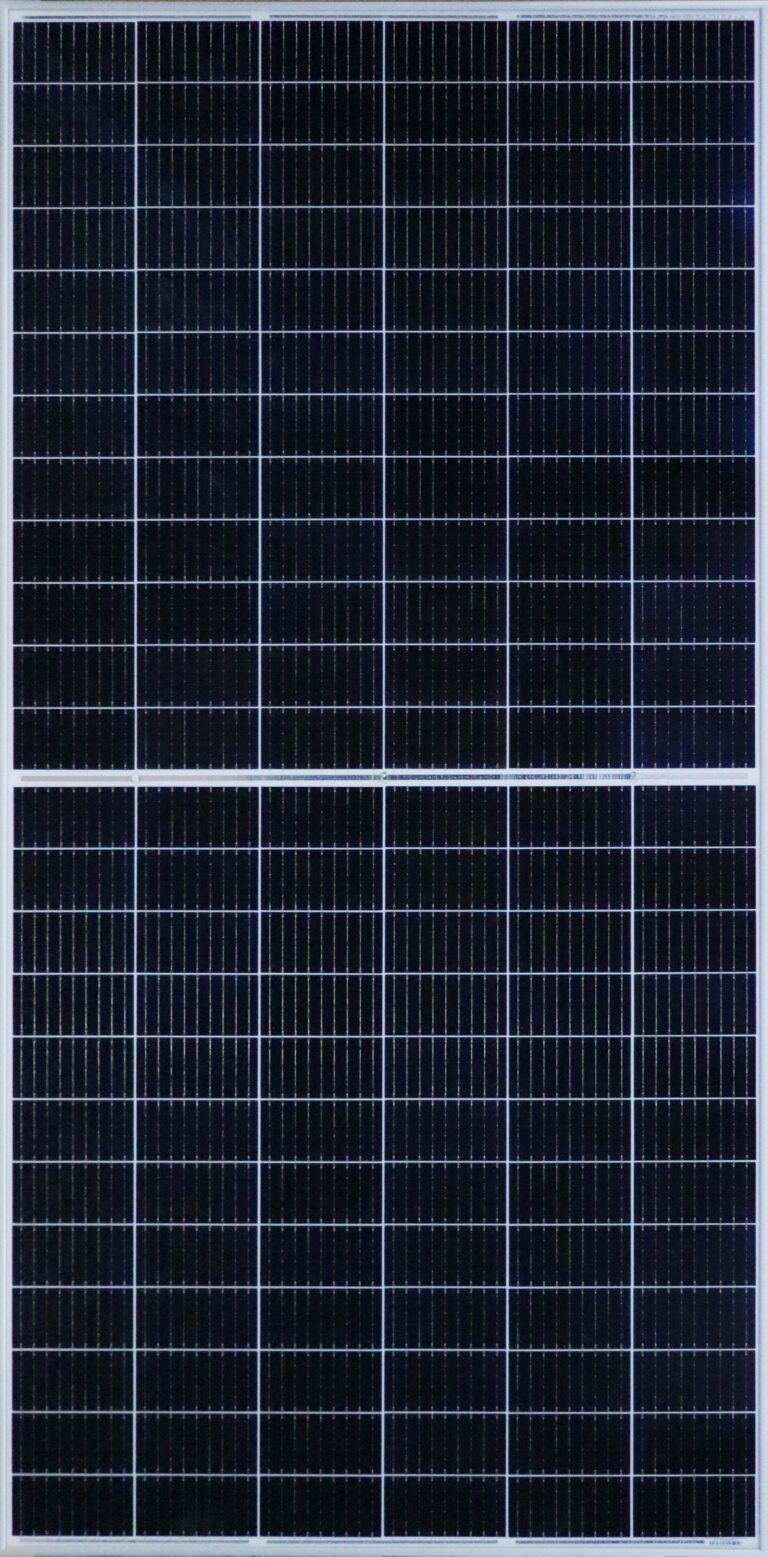

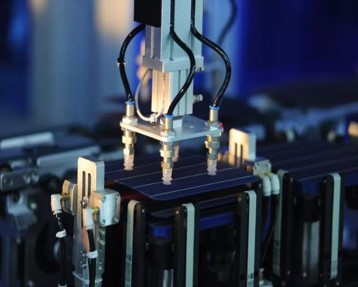

Super Multi BusBar (SMBB) solar cell technology is an advanced photovoltaic (PV) technology that involves using multiple thin copper or silver strips, known as “bus bars,” to connect the solar cells in a solar module. The SMBB technology is an evolution of the Multi BusBar (MBB) technology, which uses multiple bus bars to connect the cells in a solar module.

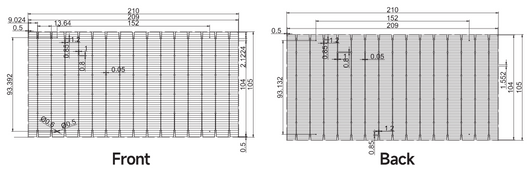

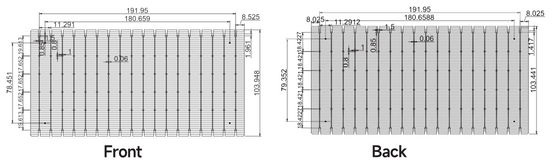

SMBB technology takes this concept further by using more bus bars, often 10 or more, to further reduce the resistance and improve the efficiency of the solar cell. The bus bars are typically arranged in a grid pattern on the front and back of the solar cell, creating a dense network of connections between the cells.

The use of multiple bus bars in SMBB technology provides several benefits, including:

Improved module efficiency: The dense network of bus bars reduces the resistance and improves the efficiency of the solar cell, resulting in higher energy output.

Better shading tolerance: The multiple bus bars provide more paths for the electrical current to flow, reducing the impact of shading on the solar cell.

Reduced hotspots: The reduced resistance and improved current flow also reduce the risk of hotspots, which can occur in areas of the cell with high resistance.

SMBB technology is relatively new and has not yet been widely adopted in the PV industry. However, some manufacturers have started to incorporate this technology into their solar modules, and it is expected to become more prevalent as the technology continues to evolve and improve.

SMBB 15 /18 BusBars technology - advantages

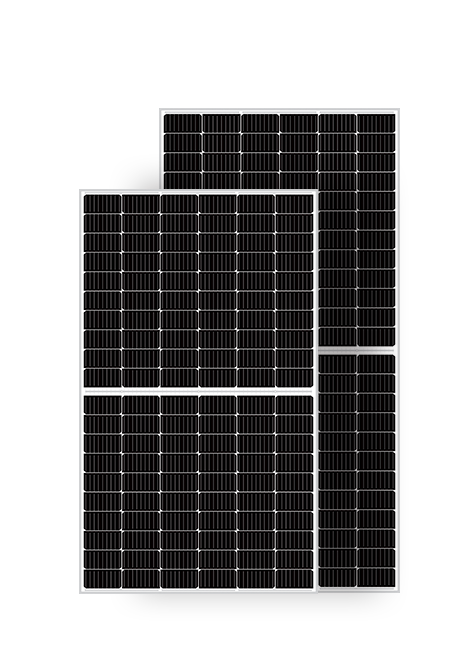

- The larger surface area of photovoltaic cells, but still in the most popular mounting standard up to 210 mm solar cells size. Thus, more power is obtained from one PV panel.

- Reduced BusBars help the PV module to increase efficiency in the same area.

- Improved efficiency: SMBB technology reduces the electrical resistance in the solar cell, enabling more efficient electron flow and increasing the cell's overall energy conversion efficiency. This improved efficiency translates to higher energy output from the same amount of sunlight, making SMBB solar cells more productive.

- Certainly, the greater number of BusBars reduces the spacing between the busbars. Therefore, the path of flowing current is shortened, which in turn reduces energy losses resulting from resistance.

- Enhanced shading tolerance: The multiple thin bus bars in SMBB cells create multiple pathways for electrical current, making them less susceptible to power loss caused by partial shading. This increased shading tolerance is especially beneficial in installations where partial shading from objects like trees or buildings can impact solar panel performance.

- Reduced hotspots: By distributing the electrical current more evenly across the cell surface, SMBB technology helps minimize hotspots—areas of localized heating due to high resistance. Hotspots can lead to decreased efficiency and long-term cell degradation, and SMBB technology helps mitigate these issues.

- Lower series resistance losses: The use of numerous bus bars in SMBB cells reduces the series resistance losses, further enhancing their overall performance and increasing the energy yield of the solar panels.

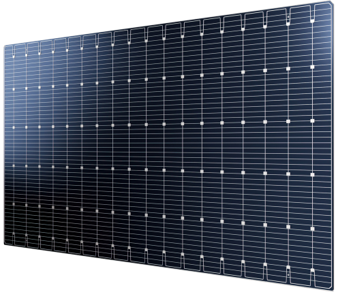

Mysolar HJT SOLAR PANEL

Overall, SMBB technology represents a significant step forward in solar cell design, helping to improve photovoltaic systems’ performance, efficiency, and reliability, which are vital for the widespread adoption of renewable energy sources and combating climate change.

HJT G12 SMBB Solar Cells

The HJT G12 solar cells are characterized by their unique structure, combining monocrystalline silicon with thin amorphous silicon layers. This heterojunction structure aims to reduce electron recombination losses and improve overall cell efficiency by minimizing energy loss during the conversion process. The most innovative BusBar technology with G12 (210mm) cells gives several new advantages for heterojunction solar modules.

Here are some key features and standards associated with G12 HJT solar cells:

High Efficiency: G12 HJT solar cells are known for their high energy conversion efficiency, which can exceed traditional monocrystalline or polycrystalline solar cells. The HJT technology helps achieve higher efficiency by enhancing the electron transport properties.

Low-Temperature Coefficient: G12 HJT solar cells typically have a low-temperature coefficient, meaning their efficiency drop with increasing temperature is lower compared to conventional solar cells. This characteristic makes them well-suited for regions with high-temperature environments.

Excellent Low Light Performance: The heterojunction structure of G12 HJT cells allows them to perform well under low-light conditions, such as during cloudy days or in the early morning and late afternoon, leading to higher energy yield.

Durable Design: HIT solar cells have demonstrated good long-term reliability and durability, ensuring stable performance over the years.

Aesthetic Appeal: G12 HJT solar panels often come with a sleek, all-black design, making them aesthetically pleasing for residential and commercial installations.

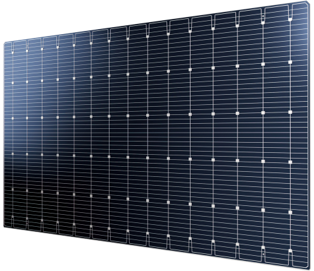

HJT Solar Cells 15BB/18BB (super multi busbar)

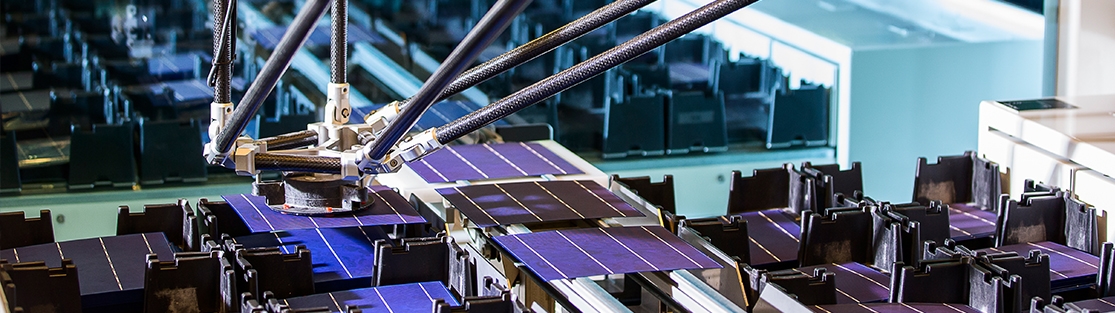

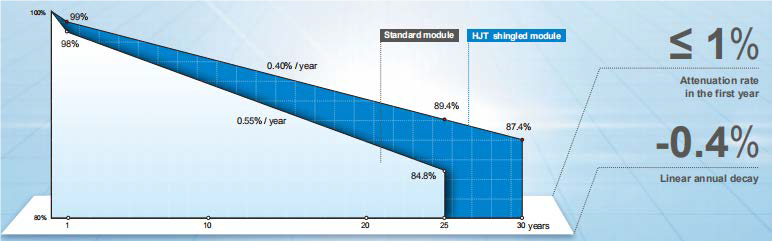

As one of the best in the new generation of high-efficiency solar cells, HJT technology leads a new round of revolution in PV technology. With a single hybrid structure integrating the advantages of crystalline silicon and amorphous silicon thin film technology, HJT solar cell has the advantages of high efficiency and stability with a low-temperature and simplified manufacturing procedures.

Extremely low-temperature coefficient so as to avoid LID and PID effect. There is no color difference between the front and back side, the bifaciality is more than 95%. The backside has an obvious advantage in power generation, which ensures a stable and high-efficiency power output regardless of seasonal circulation and climate change.

HJT technology is one of the best among the new generation of high-efficiency solar cells, leading a revolution in PV technology. HJT solar cell has a hybrid structure that combines the benefits of crystalline silicon and amorphous silicon thin film technology. As a result, it has high efficiency and stability, and a simplified and low-temperature manufacturing process.

It has an extremely low-temperature coefficient, thereby avoiding the LID and PID effect. There is no difference in color between the front and back sides, and the bifaciality is over 95%. The backside has a clear advantage in power generation, ensuring a stable and efficient power output irrespective of seasonal and climate changes.

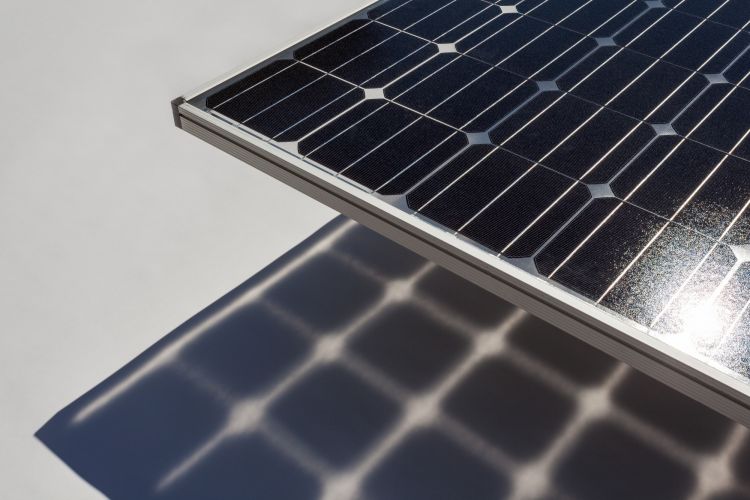

High reliability of Multi Bus Bar technology

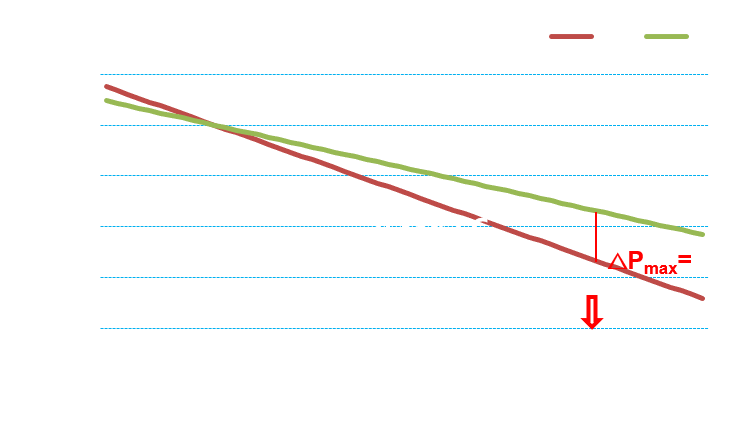

The current generated by the fine busbar is conducted to the main busbar of the PV panel. Consequently, if the busbar is broken or damaged, some of the currents cannot be transferred to the main busbar. The consequence of which is the incorrect operation of the cell, which is manifested by a low short-circuit current and low output power.

In traditional panels, the distance of a single busbar from the main busbar is long, so if the panel power is damaged, the power of the panel is completely lowered.

However, in the case of solar cells using 9BB/12BB technology, these distances are shorter. Consequently, when the busbar fails, the power of the panel will not be degraded much.

Solar panels with MBB technology have higher reliability. They are resistant to mechanical stress, therefore they are resistant to microcracks, snow, rain and other weather anomalies. The Multi BusBar technology reduces the stress on the solder strip, which reduces the risk of breaking the Bus Bar.

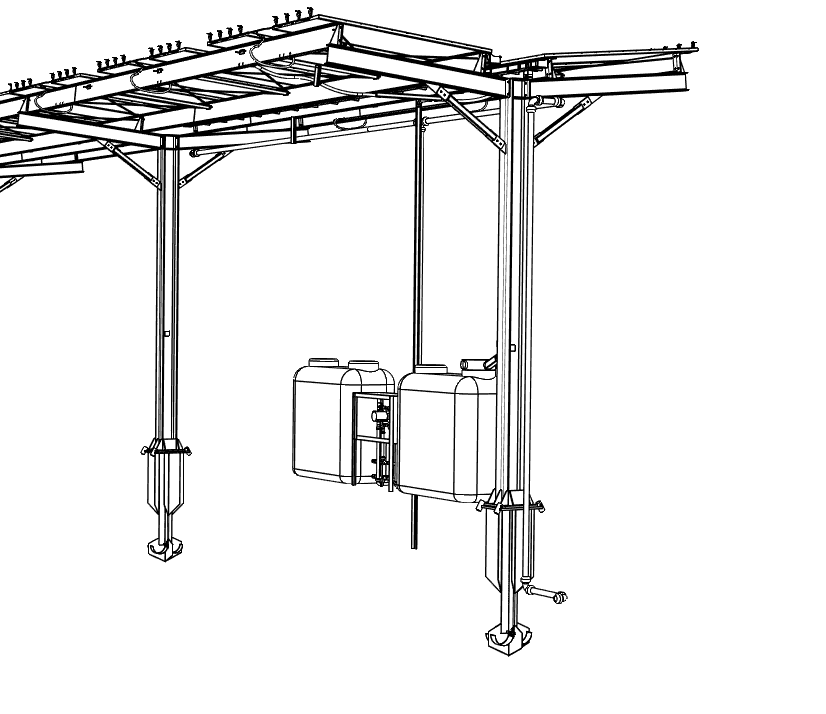

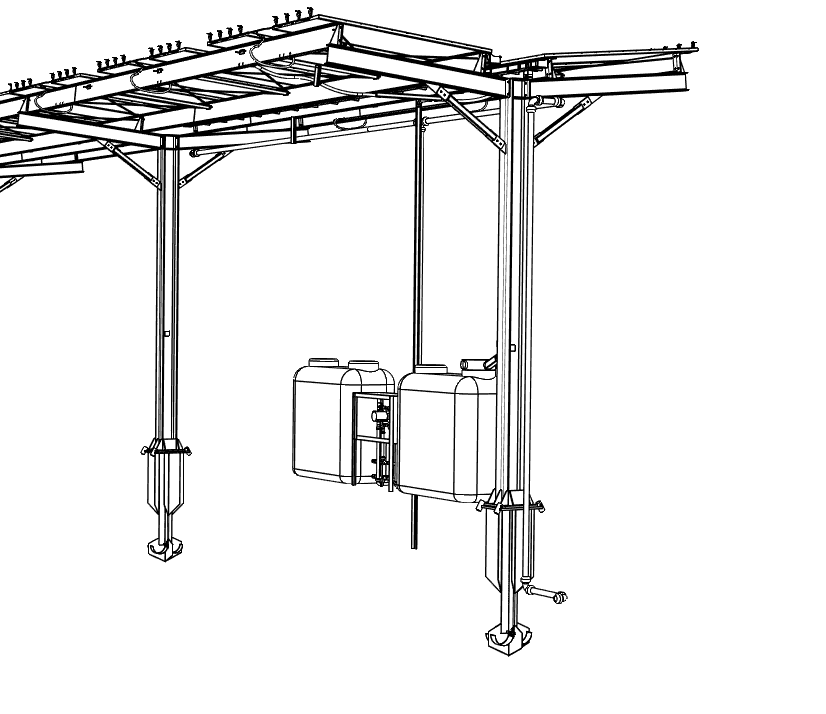

Multi BusBar tech for utility-scale installations?

The production technology of the BusBar 9BB/12BB system is crucial in high-power installations. Undoubtedly, in these installations, aspects such as the area occupied, power from one module, safety and durability make up a large whole. Therefore, MBB modules are optimal for:

- solar farms,

- large commercial installations,

- farm photovoltaics,

- PV installations for condominiums.

Most Popular

Kapaciteti Srbije za Fotonaponsku (PV) Energiju

Serbia Capabilities for Photovoltaic (PV) Energy

Subscribe To Our Weekly Newsletter

Categories

- HJTPV.com

- HJT Technology

- HJT Producers

- HJT Solar Panels

- HJT Solar Panel Mysolar Gold 740W

- HJT Solar Panel Mysolar Gold 640W

- HJT Solar Panel AEsolar COMET 720W

- HJT Solar Panel AESOLAR COMET 650W

- HJT Solar Panel Bi Chaser Akcome 120 Cells

- HJT Solar Panel HuaSun HS-B120DS

- HJT Solar Panel Jinergy JNHM120 Cells

- HJT Solar Panel Risen Hyper-ion

- HJT Solar Panel QW Solar Giwa5 730W

- HJT Solar Panel QW Solar Giwa5 640W

- HJT Solar Panel Risen RSM120

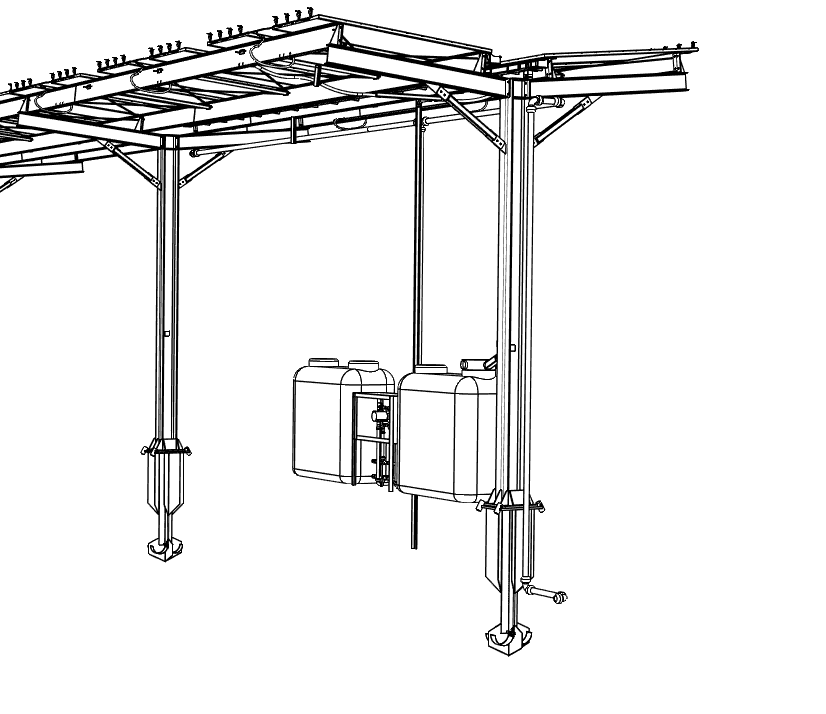

- Cleaning Robot

- HJT Solar CELLS

- News&Knowledge

- Contact

- HJTPV.com

- HJT Technology

- HJT Producers

- HJT Solar Panels

- HJT Solar Panel Mysolar Gold 740W

- HJT Solar Panel Mysolar Gold 640W

- HJT Solar Panel AEsolar COMET 720W

- HJT Solar Panel AESOLAR COMET 650W

- HJT Solar Panel Bi Chaser Akcome 120 Cells

- HJT Solar Panel HuaSun HS-B120DS

- HJT Solar Panel Jinergy JNHM120 Cells

- HJT Solar Panel Risen Hyper-ion

- HJT Solar Panel QW Solar Giwa5 730W

- HJT Solar Panel QW Solar Giwa5 640W

- HJT Solar Panel Risen RSM120

- Cleaning Robot

- HJT Solar CELLS

- News&Knowledge

- Contact

Related Posts

Maximizing Agrivoltaic Performance with HJT/TOPCon Modules

MySolar a solar panel manufacturer, announced in 2023 that it has launched commercially available HJT + perovskite solar cells with a power output of 250 W. The company was founded in 2013 and has since become one of the leading solar panel manufacturers in Poland. HJT + perovskite cells are a new technology with the potential to revolutionize the solar industry.

Innovative 5MW Solar Farm in Northern Italy: Energy Excellence Meets Sustainable Agriculture

MySolar a solar panel manufacturer, announced in 2023 that it has launched commercially available HJT + perovskite solar cells with a power output of 250 W. The company was founded in 2013 and has since become one of the leading solar panel manufacturers in Poland. HJT + perovskite cells are a new technology with the potential to revolutionize the solar industry.

Kapaciteti Srbije za Fotonaponsku (PV) Energiju

Kapaciteti Srbije za PV Instalacije 1. Obilje pogodnog zemljišta: Srbija ima velike površine zemljišta pogodnog za fotonaponske (PV) instalacije. Topografija zemlje uključuje ravne ravnice, posebno

Serbia Capabilities for Photovoltaic (PV) Energy

Serbian Land Capabilities for PV Installations 1. Abundance of Suitable Land:Serbia has vast expanses of land suitable for photovoltaic (PV) installations. The country’s topography includes